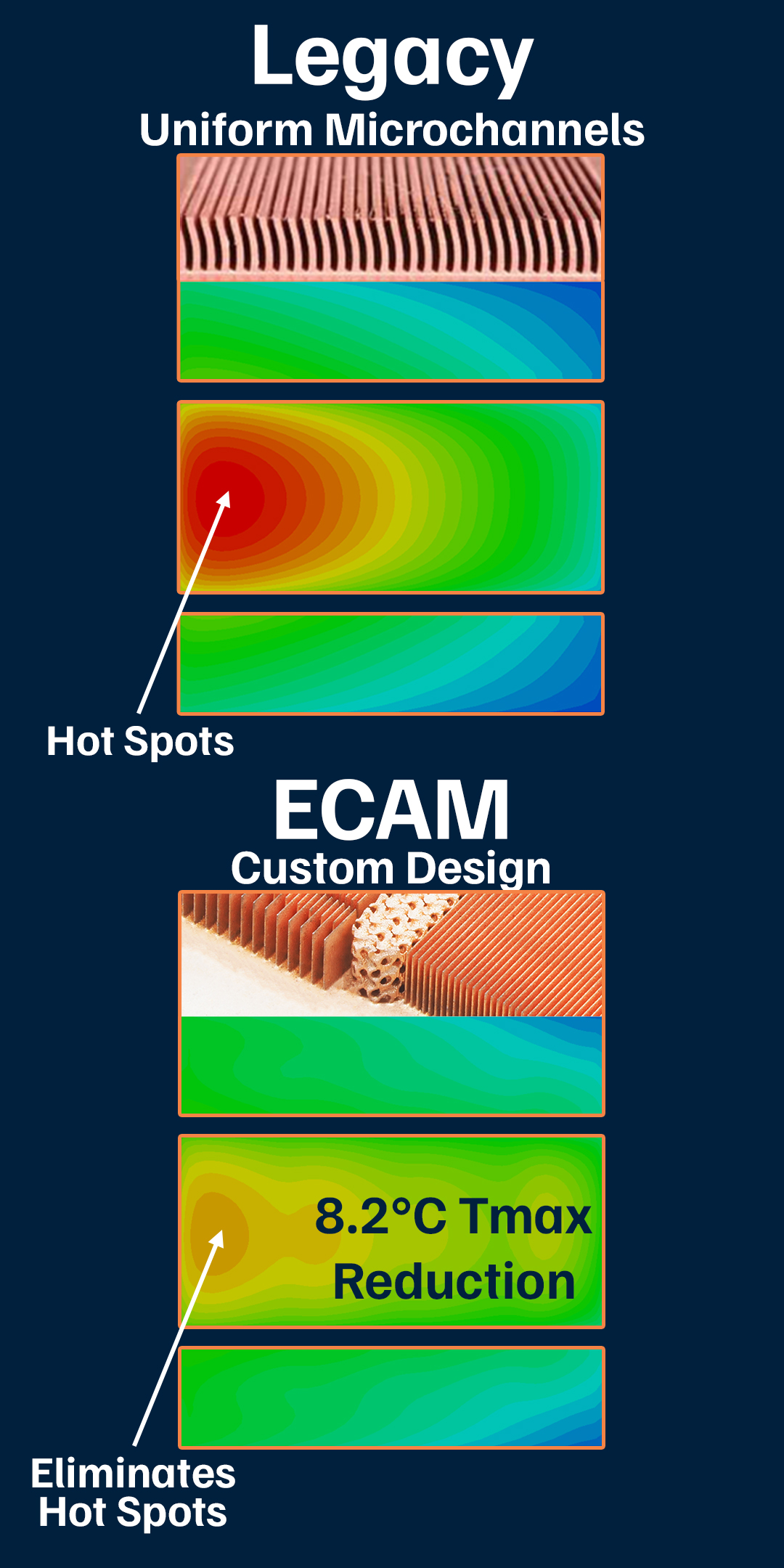

ECAM vs Legacy Cooling

Up to 8.2°C cooler, enabling higher performance and greater reliability. Discover how ECAM enables future AI data centers without requiring rack redesign.

Legacy Liquid Cooling Was Built For Yesterday’s Thermal Profiles

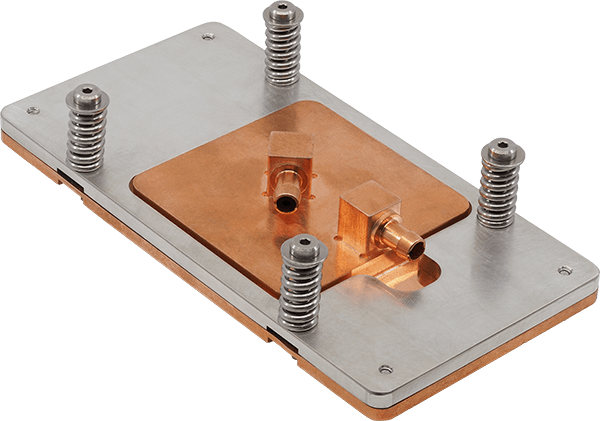

Skived and machined cold plates are simple and fast, but they were designed for lower, uniform heat loads. As AI accelerators and custom silicon drive non-uniform power maps and rising rack densities, conventional methods struggle to target hotspots and sustain efficiency.

What limits legacy approaches

- Uniform fin geometries cannot address non-uniform die maps

- Internal features are constrained by subtractive tooling

- Higher power densities have pushed the limits of skived options

- Designs do not align with future roadmaps like direct-to-silicon integration or immersion boiling

In environments where cooling can consume a large share of facility power, every degree of headroom matters.

ECAM: Purpose-Built For What's Next

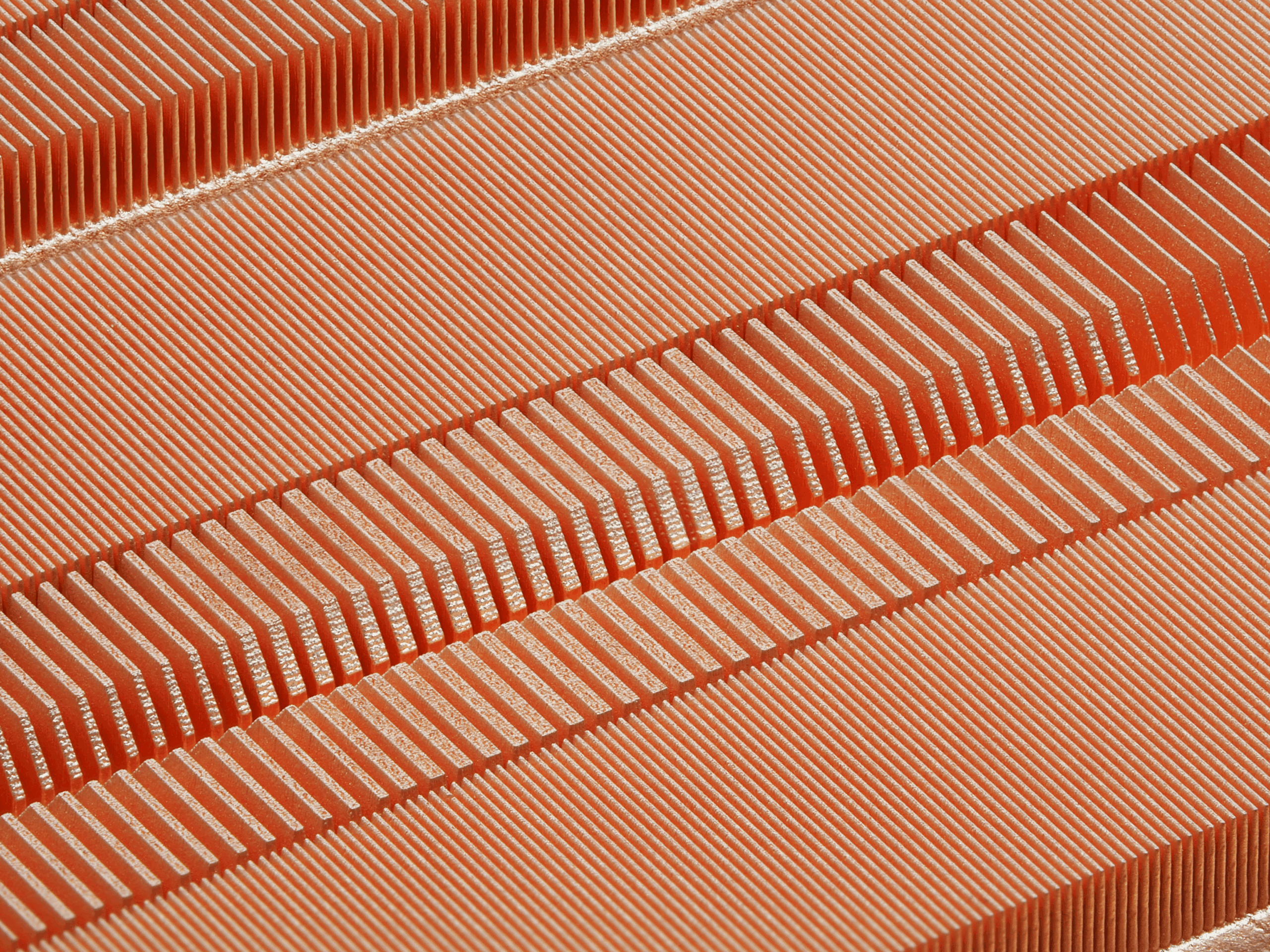

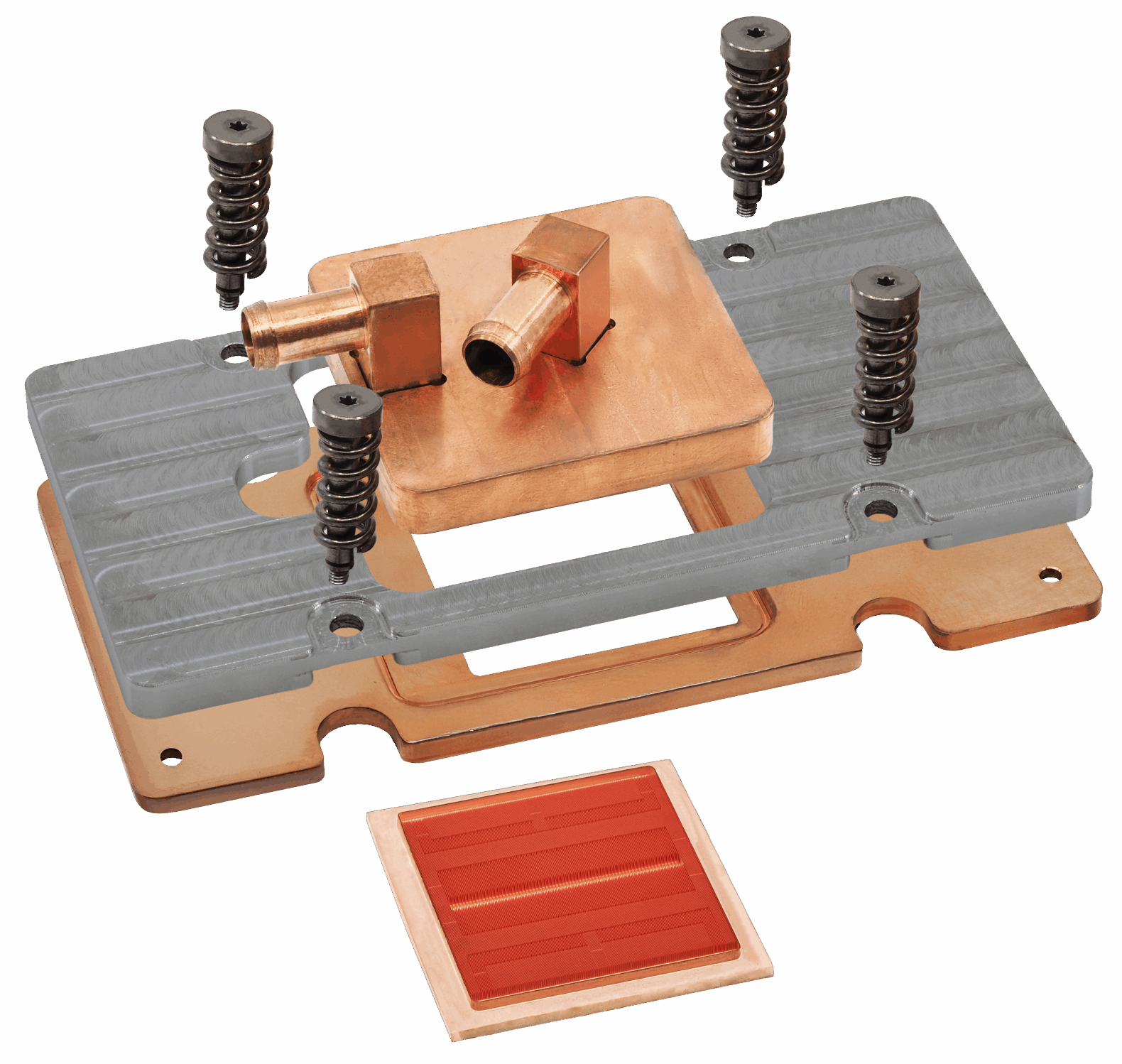

Electrochemical Additive Manufacturing creates pure copper cooling structures at micron scale in geometries optimized for your device’s power map. The result is a single-phase cold plate solution that reduces thermal resistance, lowers cooling energy, and scales with you.

Key Differentiators:

- Targeted flow paths: Channel geometry steers coolant to known hotspots for higher die temperature uniformity

- Deployment-ready fit: Adoption in new builds, with envelopes that align to current manifolds and supply chains

- Digital manufacturing: From CAD to production with optimized designs tuned to the device’s power map

- Scalability: From pilot lots to high-volume production with consistent quality

At Computex 2025, Wiwynn featured a 3.5 kW cold plate enabled by ECAM in partnership with Fabric8Labs, engineered for high-power AI servers and reported to deliver up to 48 percent better thermal-hydraulic performance than legacy skived microchannels.

ECAM vs Legacy Technical Study

Looking to dive deeper into how ECAM-enabled cold plates outperform traditional solutions? Our technical white paper includes thermal performance data, real-world use cases, and design benchmarks.

ECAM vs Legacy—30-Second Summary

- Greater thermal performance: Up to 8.2°C lower Tmax at matched conditions and fewer hotspots with ECAM design optimized to your device power map

- Aligned with your vendors: Copper materials, QA processes, and mechanical envelopes that work within existing supply chains

- Improved reliability: Apply ECAM thermal headroom to reduce throttling

Ready For Next Gen Liquid Cooling?

Stop planning tomorrow’s AI deployments with yesterday’s cooling geometry. ECAM delivers cooler devices, lower cooling energy, and device specific designs, all optimized for your deployment.

Request a Thermal Design Review

ECAM Enables Best-In-Class Liquid Cooling

Unlock Mass-Customized, High-Performance Cooling with ECAM. Rapidly deploy optimized thermal solutions tailored for your most demanding high TDP applications. Get the technical data and performance curves – download our B200 case study.