MARKETS

ECAM's precision, efficiency, and material versatility is transforming manufacturing across industries, enabling countless game-changing applications.

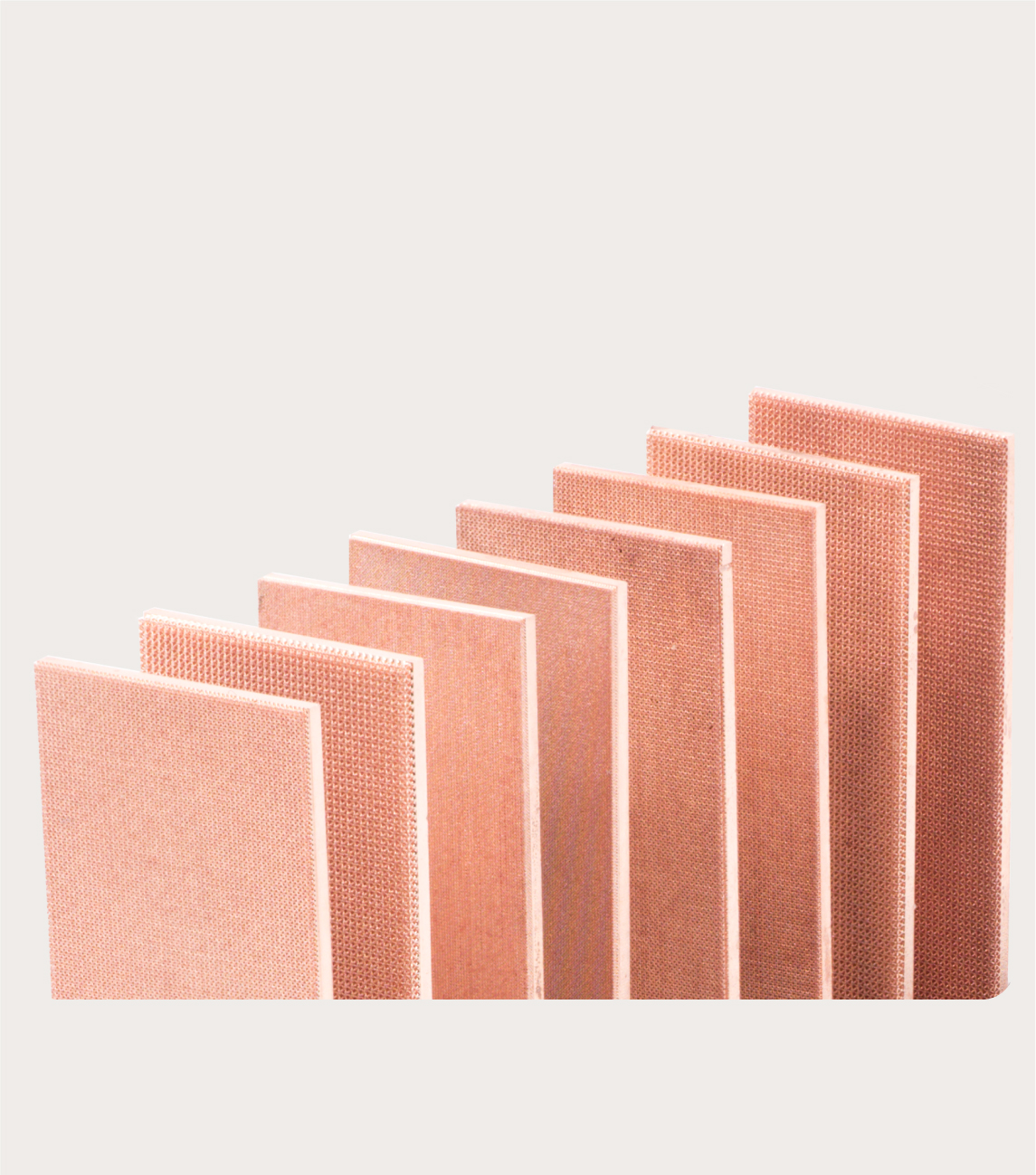

THERMAL MANAGEMENT

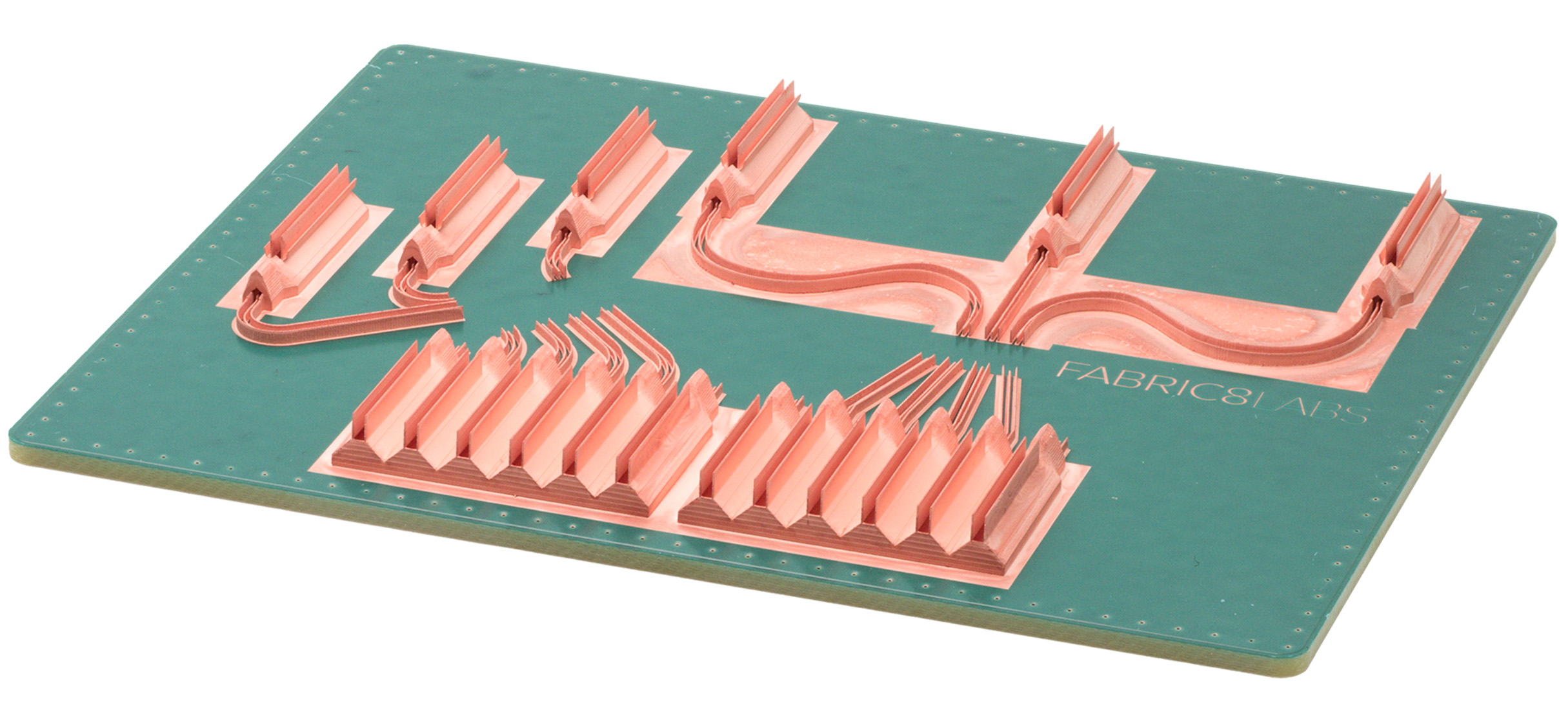

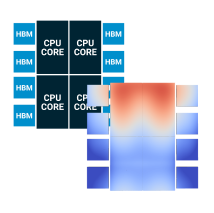

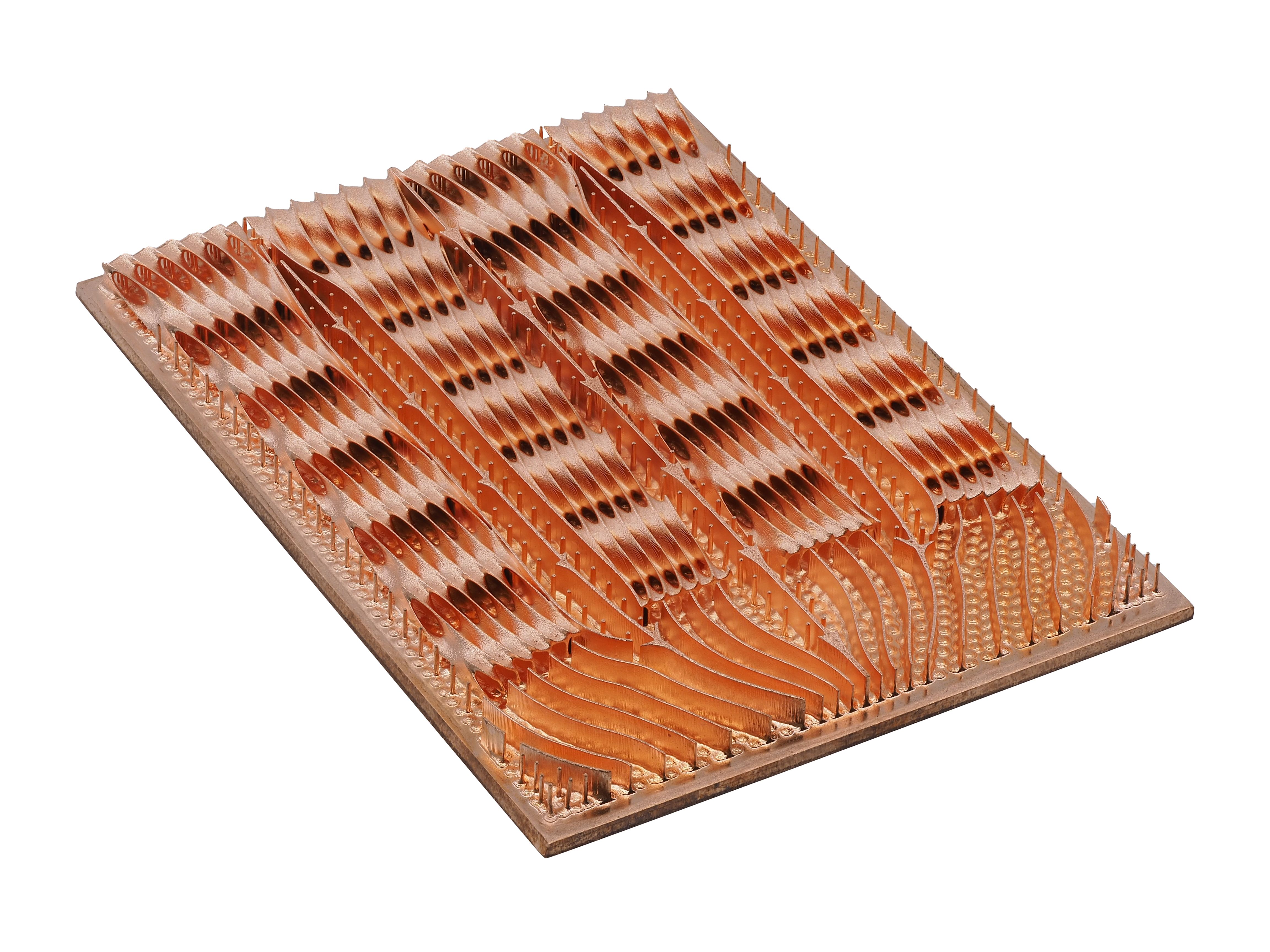

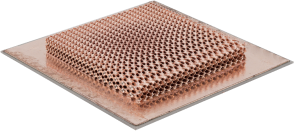

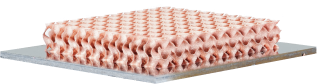

Fabric8Labs collaborates with customers to produce AI-optimized thermal solutions based on their application’s unique power map.

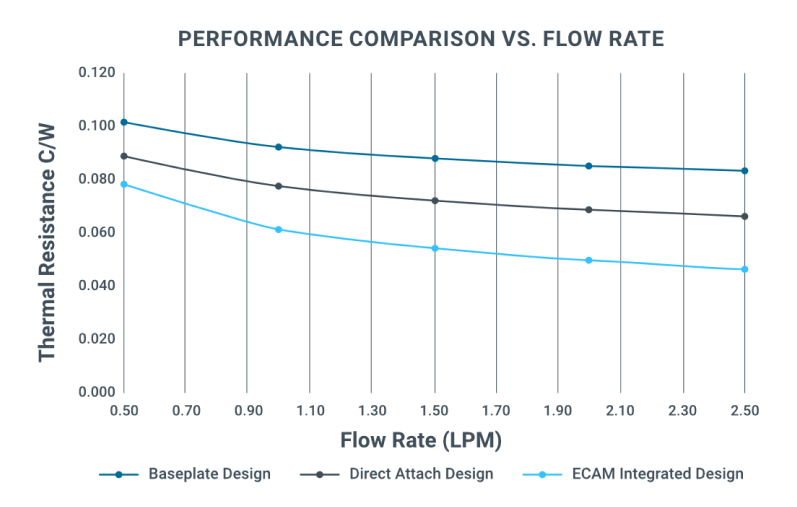

We improve the thermal performance of CPU/GPU cooling hardware by more than 100%, enabling the thermal design power (TDP) roadmap of next-generation AI/ML hardware.

- Stress Free Pure Copper

- Application Specific Designs With 33 Micron Resolution

- Print Direct To Metal Foil, Ceramic & Packaged Silicon

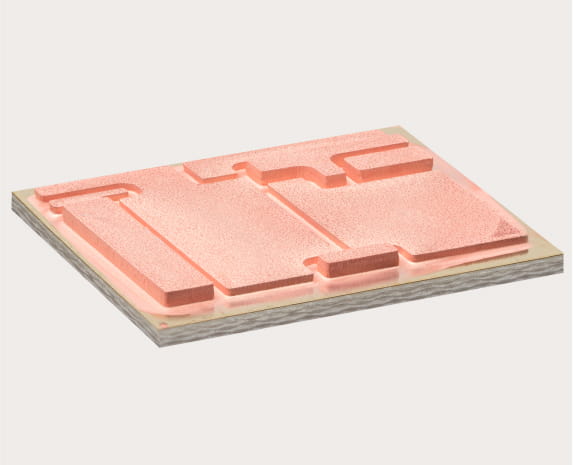

CUSTOM POWER MAP OPTIMIZED COOLING SOLUTION

MAXIMIZE PERFORMANCE

LOWER TCO

Custom cooling solutions

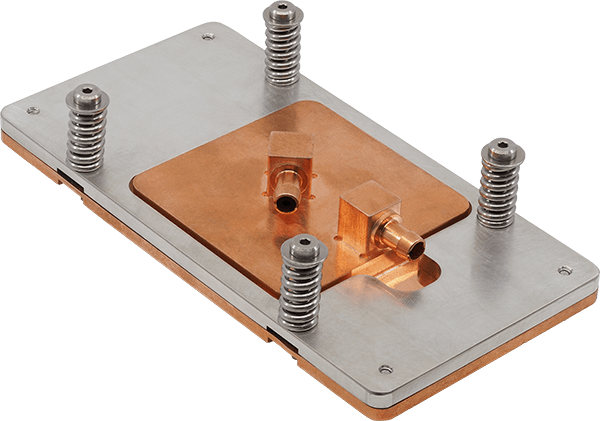

ECAM Enables Best-In-Class Liquid Cooling

Unlock Mass-Customized, High-Performance Cooling with ECAM. Rapidly deploy optimized thermal solutions tailored for your most demanding high TDP applications. Get the technical data and performance curves – download our B200 case study.

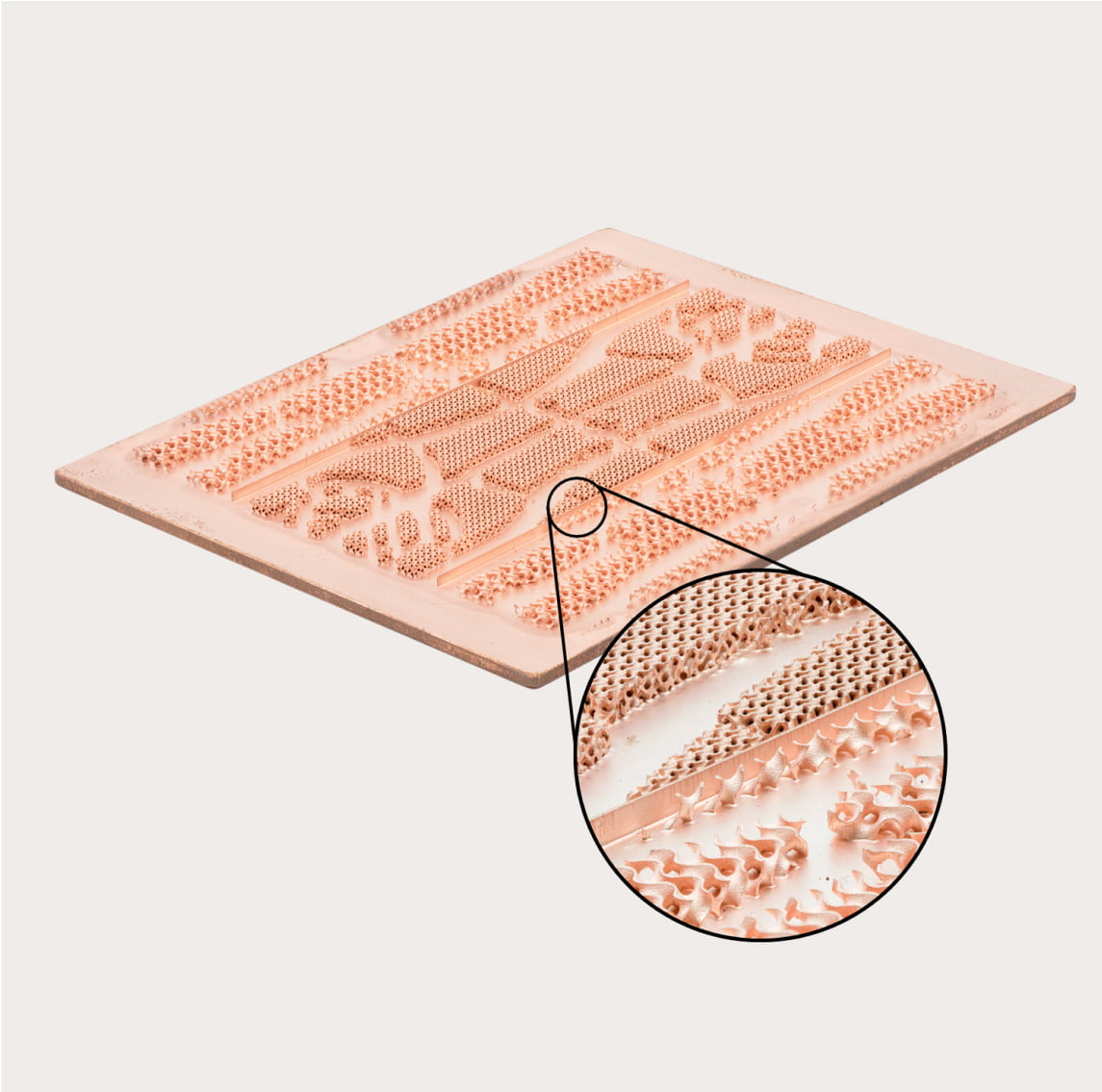

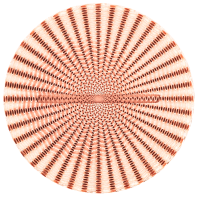

WIRELESS COMPONENTS

Our technical experts collaborate with customers to produce AI-optimized 3D antennas, low loss RF filters and waveguides for high frequency (Ka through Y band) applications that provide higher Gain, HPBW, and VSWR performance.

- Pure Metal Deposition At Room Temperature

- Printing Direct To Circuit Boards

- High Resolution Printing Of Features Optimized for mmWave Applications

Improved axial ratio and UWB performance

LOW SURFACE ROUGHNESS

CMMC LEVEL II CERTIFIED

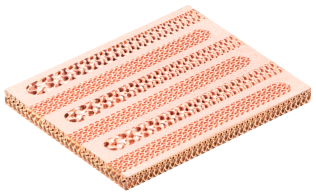

POWER ELECTRONICS

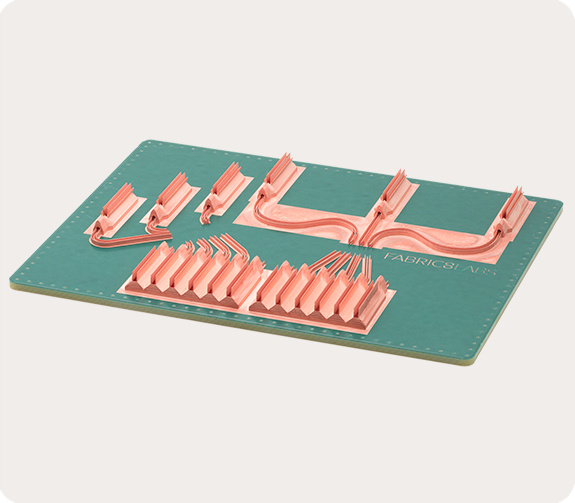

Our technical experts collaborate with customers to produce ceramic-based substrates for power electronics applications with pure copper printed at customized thicknesses for power and signal traces, as well as integrated thermal management structures.

- Print Directly Onto Ceramics (SiN, Al2O3, etc.)

- Stress-free, High Conductivity Copper Structures Printed At Room Temperature

- Integrated Thermal Management Features On DBC Substrates To Remove TIM

DIRECT PRINT TO REMOVE TIM

Reduce overall package size

IMPROVED THERMAL

PERFORMANCE

EMERGING APPLICATIONS

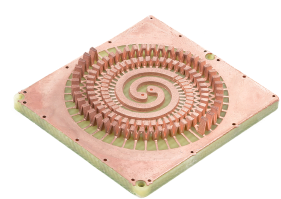

Our technical experts collaborate with customers to produce products for a wide range of conductive materials for catalysis, medical devices, connectors and micro-mechanical components.

ECAM’s exceptional printing resolution surpasses traditional techniques and is crucial for intricate micro-medical components. Unlike traditional methods that require high temperature processing, ECAM builds at room temperature. The result, no thermal stresses and no warping, which is essential for maintaining the precise structures for electronics and micro medical components.

- High Resolution & Geometric Freedom

- Room Temperature Deposition Without Post-print Deformation

- Wide Range of Alloy-systems Available

Increased surface area

Combine geometries for optimized performance