Precision Takes Flight

Unlocking performance, weight, and integration gains for every mission profile.

Why SWaP-C Rules Aerospace Design

-

Every mission profile—whether in LEO, defense, or commercial aviation—demands electronics that are smaller, lighter, and more capable.

-

Thermal management, RF performance, and electronics density now set the upper limits of system potential.

-

Traditional manufacturing can’t deliver the complexity, miniaturization, or cost efficiency needed for next-gen phased array antennas and tightly integrated electronics.

-

To achieve breakthrough performance, aerospace leaders are moving beyond legacy processes—embracing advanced additive solutions that meet aggressive SWaP-C targets without compromise.

ECAM: The Aerospace Advantage

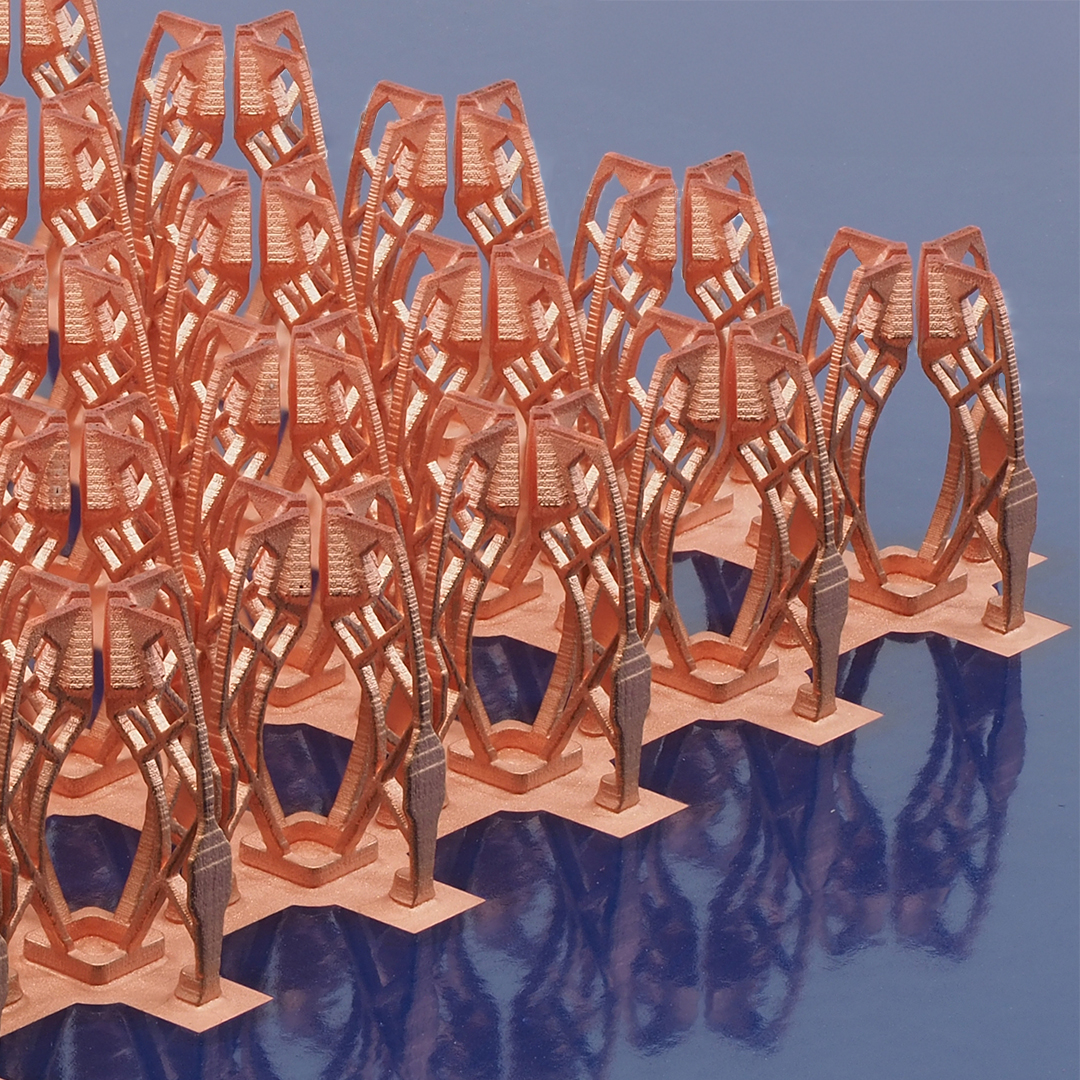

Aerospace platforms can no longer afford the mass, thermal inefficiencies, or integration challenges of traditional manufacturing. Fabric8Labs’ Electrochemical Additive Manufacturing (ECAM) offers a fundamentally different approach—printing high-purity metal features only where they deliver value, with no wasted material or excess mass. This digital, atom-by-atom process produces lightweight, high-density components perfectly tailored to the most aggressive SWaP-C requirements.

With ECAM, designers can shrink the size and weight of antennas, electronics, and thermal assemblies without sacrificing performance. Monolithic, pure copper parts are printed at micron-scale precision, enabling complex, miniaturized designs that conventional processes simply can’t match. And because ECAM operates at room temperature, sensitive substrates like PCBs, ceramics, and silicon can be used directly—avoiding thermal stress, warping, or costly post-processing.

Critically, ECAM enables a new level of functional integration. Complex cooling geometries, RF features, or interconnects can be printed directly onto electronic boards or modules. The result is a single, high-performance part—no bonding, assembly, or intermediate interfaces to compromise reliability or add cost.

The ECAM aerospace advantage:

-

Eliminate overbuild and excess weight—print only what’s needed, exactly where it’s needed.

-

Achieve industry-leading SWaP-C with dense, monolithic copper parts at micron resolution.

-

Leverage room-temperature processing for direct printing on sensitive substrates.

-

Integrate cooling, RF, and power features into a single structure—reducing assembly and failure points.

Key Aerospace Applications

3D Phased Array Antennas

ECAM enables direct-write pure copper phased arrays on PCB or LCP at room temperature—delivering higher gain, wider bandwidth, and superior array-to-array consistency. With ultra-low surface roughness (1–2 μm Ra), these antennas maintain low-loss performance even at Ka- and W-band frequencies. The process eliminates adhesives, post-processing, and alignment steps, reducing risk and accelerating production.

Miniaturized Electronics

Print monolithic, high-resolution interconnects, bus bars, and complex RF structures directly onto PCBs or ceramics. This approach dramatically reduces component size and parasitics, slashes weight, and maximizes reliability and integration density. Achieve more compact, lighter assemblies—essential for modern aerospace systems.

Advanced Liquid Cooling

Fabricate custom cold plates and microfluidic structures in pure copper, matched to each device’s power map or thermal hotspots. ECAM enables cooling structures to be printed directly onto silicon or other substrates, eliminating the need for bonding or thermal interface materials. The result: minimal pressure drop, maximum heat extraction, and optimized SWaP for total system efficiency.

Why ECAM: Quantified Impact for Aerospace

Fabric8Labs’ ECAM platform delivers measurable gains across the aerospace design cycle—from first prototype to full-rate production. By reducing size and mass without compromising performance, ECAM frees up payload capacity, extends range, and supports more capable mission profiles. Digital manufacturing accelerates design iteration with no tooling delays, enabling teams to move from concept to flight hardware in weeks instead of months.

ECAM also lowers cost per part by eliminating expensive powders, multi-step assemblies, and risk-prone post-processing. Supply chain complexity drops, with fewer vendors and fewer integration steps. And because the same platform scales seamlessly from one-off prototypes to thousands of parts, aerospace programs can de-risk early development while preparing for efficient high-volume production without process changes.

Key outcomes:

-

Higher payload or range through reduced system mass

-

Rapid prototyping and design iteration with no tooling delays

-

Lower part cost and simplified supply chain

-

Smooth scale-up from prototype to production

Technical Snapshot

ECAM’s performance metrics prove its readiness for aerospace-critical applications, combining material purity, precision, and reliability at the highest levels.

-

Pure copper structures: >99% density, 380 W/m·K thermal conductivity—ideal for high-efficiency thermal and electrical performance.

-

Phased array antenna: Ka- and W-band ready, <2 μm surface roughness for low-loss signal transmission, printed direct to PCB or LCP with no adhesives.

-

Thermal management: <0.01 °C/W thermal resistance and 0.5 psi pressure drop at 1 LPM. Fully customizable microfluidic geometry tailored to unique power maps and hot spots.

These data points demonstrate ECAM’s ability to meet or exceed the stringent requirements of modern aerospace platforms—across RF, electronics, and thermal systems—while delivering the integration and SWaP-C advantages mission planners demand.

CERTIFICATIONS

DRARS COMPLIANT

ITAR REGISTERED

NIST SP 800-171

Work with Fabric8Labs

From first concept to flight-ready hardware, our team partners with you at every stage of the program. We bring deep expertise in aerospace thermal management, RF systems, and high-performance electronics—ensuring your designs are optimized for SWaP-C, manufacturability, and mission success.

Whether you’re exploring new antenna architectures, miniaturizing electronics, or pushing the limits of thermal performance, we provide expert engineering support from early prototyping through flight qualification. With ECAM, you can iterate rapidly, validate designs with confidence, and scale production without changing platforms or processes.

Let’s accelerate your next program—together.