Introduction

While AI breakthroughs grab headlines, the real constraint to scaling performance isn’t more GPUs—it’s getting rid of the heat they generate. As accelerators climb past the kilowatt mark, cooling has shifted from an engineering afterthought to the strategic bottleneck shaping what’s possible in AI.

The “Chips Are Getting Hotter” Narrative

It’s true: AI accelerators are running hotter than ever. Flagship GPUs are now pushing 1,500 W per device—a 70% jump over previous generations. According to a recent report from SemiAnalysis on the current Nvidia GPU roadmap, AI accelerators could demand up to 3,600 W per device by 2027, pushing current power and cooling technologies to their limits. That heat density stresses even the most advanced liquid cooling systems.

But rather than painting this as a looming crisis, we can frame it as the inflection point for innovation:

- The Challenge: Traditional cold plates, designed for yesterday’s wattages, are beginning to run out of headroom—inevitably causing thermal throttling, reliability risks, and skyrocketing facility cooling costs.

- The Opportunity: The liquid cooling market is projected to surpass $15 billion in five years, driven by the need for higher-density, more efficient thermal solutions.

- The Mindset Shift: Instead of fearing the heat, we should embrace it as the force driving the next wave of engineering breakthroughs.

In other words, hotter chips aren’t just a problem—they’re the spark for cooling innovation.

Why Legacy Liquid Cooling Is Failing AI

Traditional manufacturing methods, such as machining and skiving, impose geometry limits that prevent cold plates from effectively cooling modern chips’ irregular power maps. That mismatch means:

- Hotspots persist and waste thermal budget.

- Flow paths can’t be fully optimized, leading to throttling.

- Customization and optimization are not possible with skiving technology.

At scale, these inefficiencies are a performance crisis in disguise: up to 40% of a hyperscale facility’s power bill can be cooling.

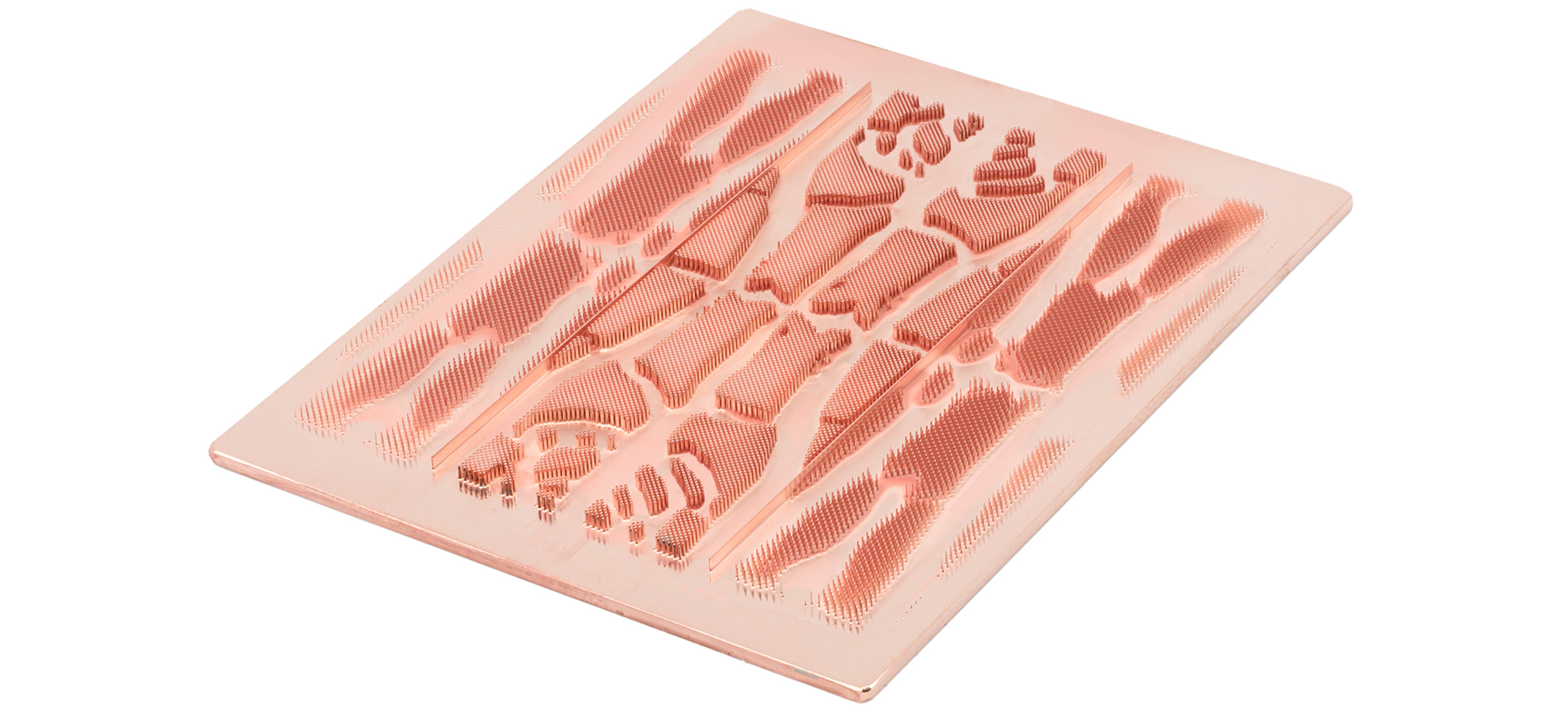

The ECAM Advantage – Real-Deployment Proof

Electrochemical Additive Manufacturing (ECAM) from Fabric8Labs is rewriting the rulebook for cold plate design and production. By printing pure copper structures at micron resolution, ECAM enables cooling channels and heat-transfer geometries impossible with conventional methods. Every design is digitally tailored to the chip’s actual power map, ensuring coolant is delivered exactly where it’s needed.

And this isn’t just a lab concept—it’s already been proven in high-profile deployments.

At Computex 2025, Fabric8Labs partnered with WiWynn to unveil a 3.5 kW ECAM-based cold plate engineered for next-gen AI infrastructure. This system demonstrated:

- Up to 48% better thermal-hydraulic performance compared to traditional microchannel cold plates.

- Precision-tuned flow paths that keep even the most power-dense AI accelerators in their optimal thermal envelope.

- Drop-in compatibility with existing infrastructure, providing scalability and ease of adoption.

This collaboration didn’t just showcase ECAM’s raw performance it also underscored its readiness for the market. ECAM is not an experimental “maybe”; it’s a deployable, production-grade solution that’s already attracting Tier-1 data center partners.

The Business Impact at Hyperscale

Adopting ECAM-optimized designs can deliver:

- Run cooler (reliability): Keep power constant and use the margin to lower Tj,max, reducing throttling risk and adding cushion for seasonal peaks, hot aisles, and transient loads.

- Push harder (performance): Hold the same device temperature and convert the margin into higher chip power/clock for more throughput.

- Raise inlet temperature (efficiency): Apply the margin to higher supply-water set points to cut plant energy, adjust for seasonal changes, and increase economizer hours

For decision makers, that’s a rare trifecta—stronger reliability, higher performance and better efficiency—chosen to fit your goals.

Cooling as the AI Enabler

AI’s growth curve shows no signs of flattening, and neither does chip power. Cooling will increasingly define competitive advantage:

- Those who adopt next-generation thermal solutions will run denser, faster, and more efficiently.

- Those who stick to legacy cooling will hit performance walls they can’t compute past.

Fabric8Labs’ ECAM platform turns cooling from a constraint into a capability by freeing AI hardware to operate at its full potential.

Take the Next Step

See ECAM in Action:

Visit our Single Phase ECAM vs Legacy Liquid Cooling page to explore side-by-side performance comparisons and discover why hyperscale operators are making the switch.