Custom Silicon Cooling

Power-Aware Thermal Design

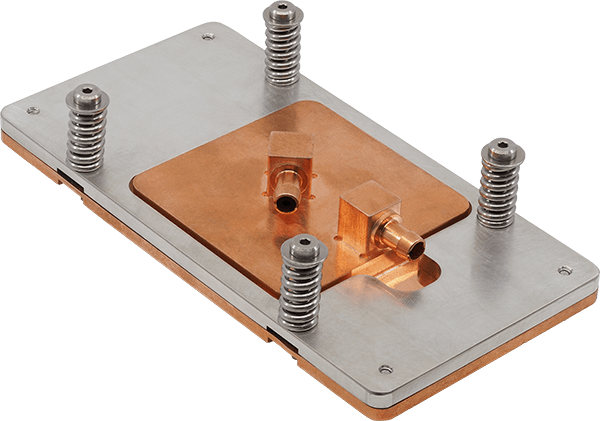

When off-the-shelf doesn’t cut it, Fabric8Labs delivers cold plates engineered from the ground up to match your device’s power map. Whether you're designing for a custom ASIC, high-density accelerator, or multi-chip module, our ECAM-powered cooling solutions meet thermal requirements others can't.

Why leading teams partner with Fabric8Labs:

-

Power Map Precision: Channels designed to target your chip’s unique hotspots

-

Accelerated Development: Skip tooling delays and launch on your schedule

-

Improve Performance: By targeting hotspots, ECAM reduces throttling and increases effective workload

Cooling Custom Silicon with ECAM

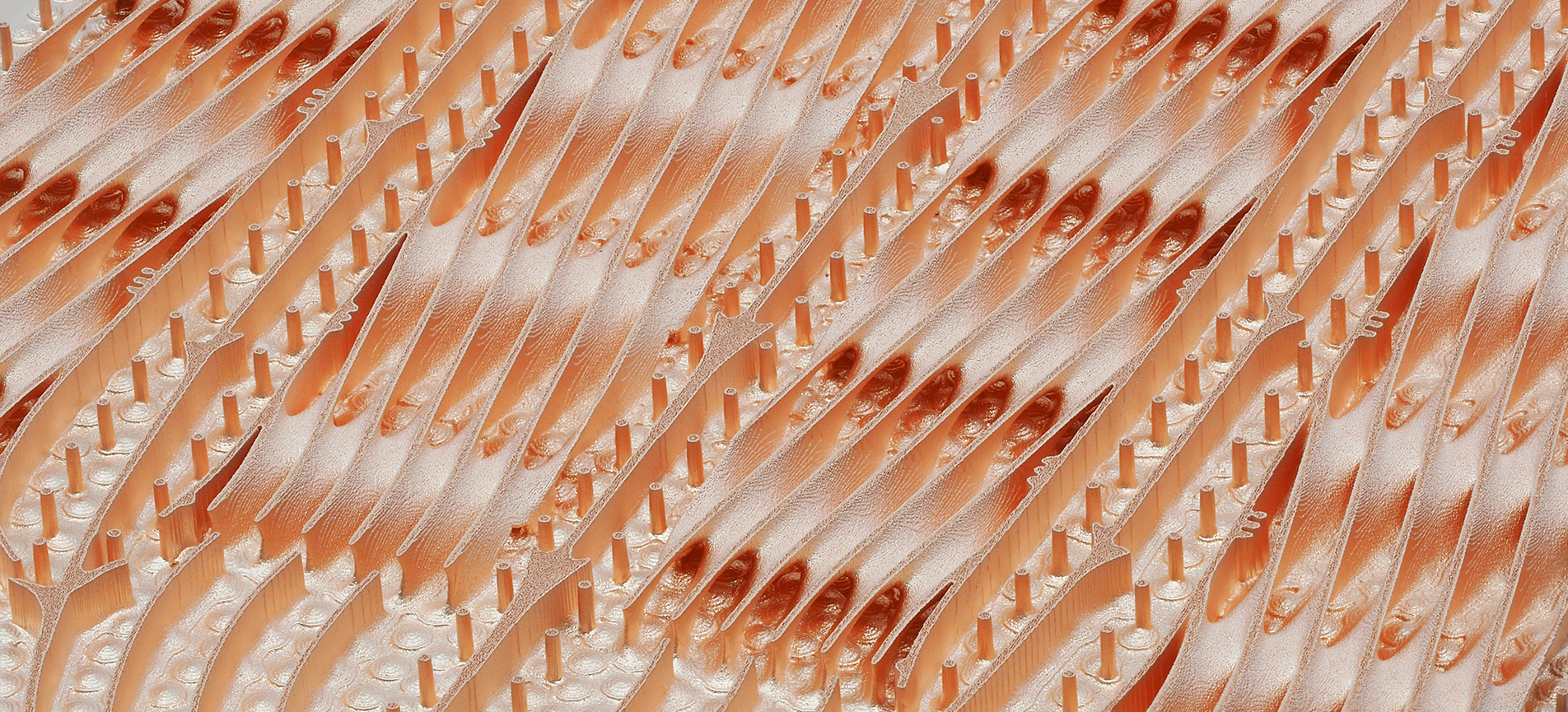

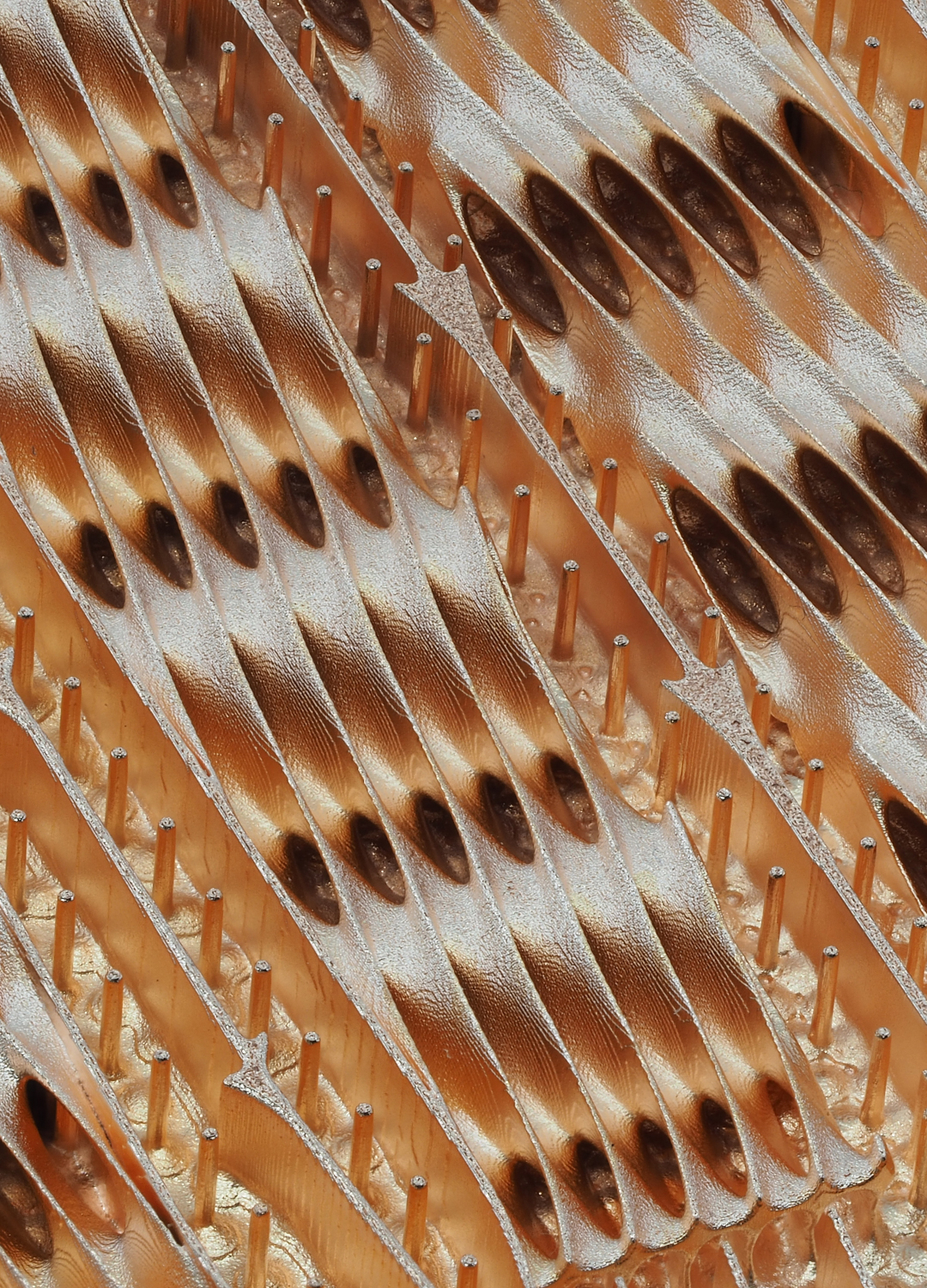

Electrochemical Additive Manufacturing (ECAM) gives you the freedom to design liquid cold plates without traditional manufacturing constraints. Instead of working around machining limits or stacked parts, ECAM grows copper from the atomic level, enabling complex internal geometries, sharp transitions, and fine feature resolution — all tailored to your application.

This process allows us to:

-

Tune every channel path to your silicon's thermal profile

-

Integrate mounting and manifold features directly into the part

-

Support performance gains across a range of flow rates and pressure drops

-

Manufacture at scale with no compromise on geometry or material quality

Whether you’re designing for ultra-thin form factors, high-wattage density, or exotic packaging, Fabric8Labs helps you unlock a new class of performance.

Prototype to Production

The ECAM platform supports the complete development cycle, from early design validation to high-volume manufacturing:

-

Rapid digital prototyping – Move from concept to functional hardware in days, enabling fast iteration and design refinement without tooling delays. This agility allows engineers to test multiple geometries in parallel and quickly converge on the optimal thermal solution.

-

Volume manufacturing – Produce high-precision inserts at scale with consistent geometry, material quality, and thermal performance. ECAM’s parallelized, room-temperature process ensures that scaling output does not compromise part accuracy or reliability, making it ideal for both niche and mass-market photonics applications.

-

Supply chain integration – Deliver fully finished, ship-to-line inserts ready for assembly by your preferred cold plate or optical module provider, ensuring seamless adoption into existing manufacturing workflows. Fabric8Labs can align production schedules, packaging, and quality assurance protocols with your current suppliers to accelerate deployment.

Proven Design Strategies

Fabric8Labs’ ECAM technology delivers cooling solutions engineered for the most demanding semiconductor and photonics applications—whether it’s GPUs in AI data centers, or high-power laser diodes and optical transceivers in advanced communication systems. Every design is optimized for both peak thermal performance and scalable manufacturability.

- Power-Map Optimization – ECAM enables microchannel geometries precisely matched to each device’s heat flux profile, targeting cooling capacity exactly where GPUs, AI accelerators, or photonic components generate the most heat.

- Hybrid Baseplate Integration – Merge conventionally machined surfaces for mechanical or optical alignment with ECAM-printed microstructures for heat removal, creating a single assembly that meets both precision alignment and extreme cooling requirements.

- Reliability at Scale – Monolithic, high-purity copper features reduce leak paths, resist fouling, and deliver stable performance over extended operating lifetimes—critical for hyperscale deployments and mission-critical optical networks.

ECAM Enables Best-In-Class Liquid Cooling

Unlock Mass-Customized, High-Performance Cooling with ECAM. Rapidly deploy optimized thermal solutions tailored for your most demanding high TDP applications. Get the technical data and performance curves – download our B200 case study.