Data Center Liquid Cooling

Lower energy costs, higher compute density, and future-proof performance.

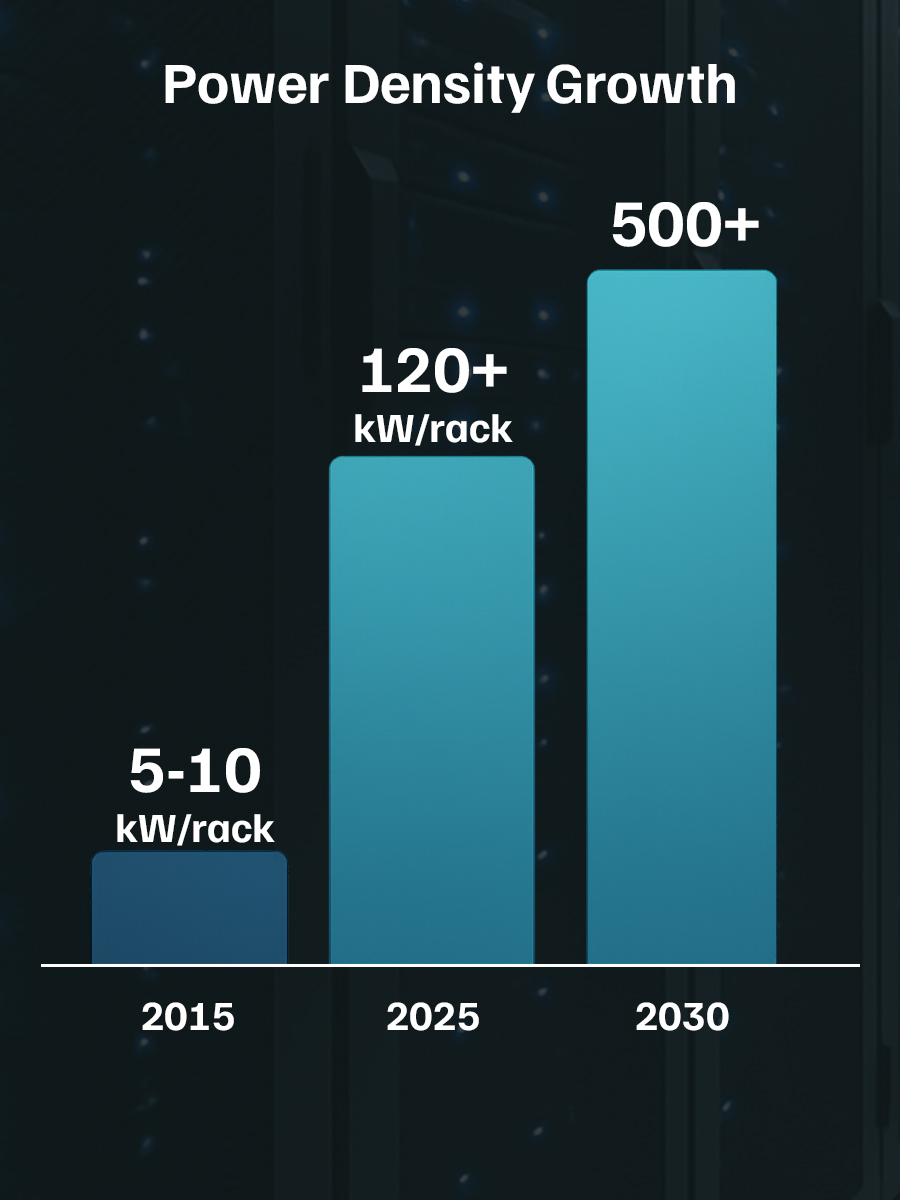

The AI Factory Cooling Challenge

Data centers powering AI, custom silicon, and hyperscale deployments are driving power densities to levels that legacy cooling hardware simply cannot manage. Traditional cold plates—designed for yesterday’s uniform loads—struggle with today’s non-uniform power maps, dense hotspots, and soaring thermal design power (TDP). The result: throttling, reliability risks, and rising energy bills that turn cooling into a boardroom-level issue.

Cooling now accounts for up to 40% of total facility energy spend, according to The Green Grid. Even marginal inefficiencies cascade into millions in OPEX, eroding margins and putting operational agility at risk. In this landscape, conventional liquid cooling and off-the-shelf cold plates are a bottleneck: they can’t adapt to evolving silicon architectures or the escalating thermal demands of modern compute.

The stakes are clear: If cooling falls behind, the entire data center slows down.

Why Conventional Cooling Fails

Legacy cold plates—machined, skived, or bonded—can’t meet the scale or complexity of next-generation data center hardware. As silicon power maps grow more irregular and rack densities skyrocket, these traditional approaches hit a wall:

- Limited Internal Complexity: Tooling and subtractive methods can’t achieve the fine, 3D-optimized features needed to target hotspots, leaving performance on the table.

- Customization is Slow and Expensive: Every new device or silicon revision requires custom tooling and long lead times, slowing innovation and driving up both prototyping and production costs.

- Innovation Bottleneck: Tooling constraints make rapid iteration impractical—teams are forced to accept “good enough” cooling, rather than application-optimized performance.

- High Energy Costs: Legacy cold plates drive high energy costs because their limited internal geometries create higher thermal resistance and pressure drop, forcing data centers to run pumps harder and chill facility water to lower temperatures to maintain safe device operation.

- Performance Ceilings: Machined or skived channels simply can’t manage the non-uniform, high-density heat loads generated by AI and custom silicon, resulting in throttling, reliability issues, and wasted energy.

Bottom line: If your cooling hardware is still built the old way, you’re locked into the past—and paying for it in lost performance, higher OPEX, and slower time-to-market.

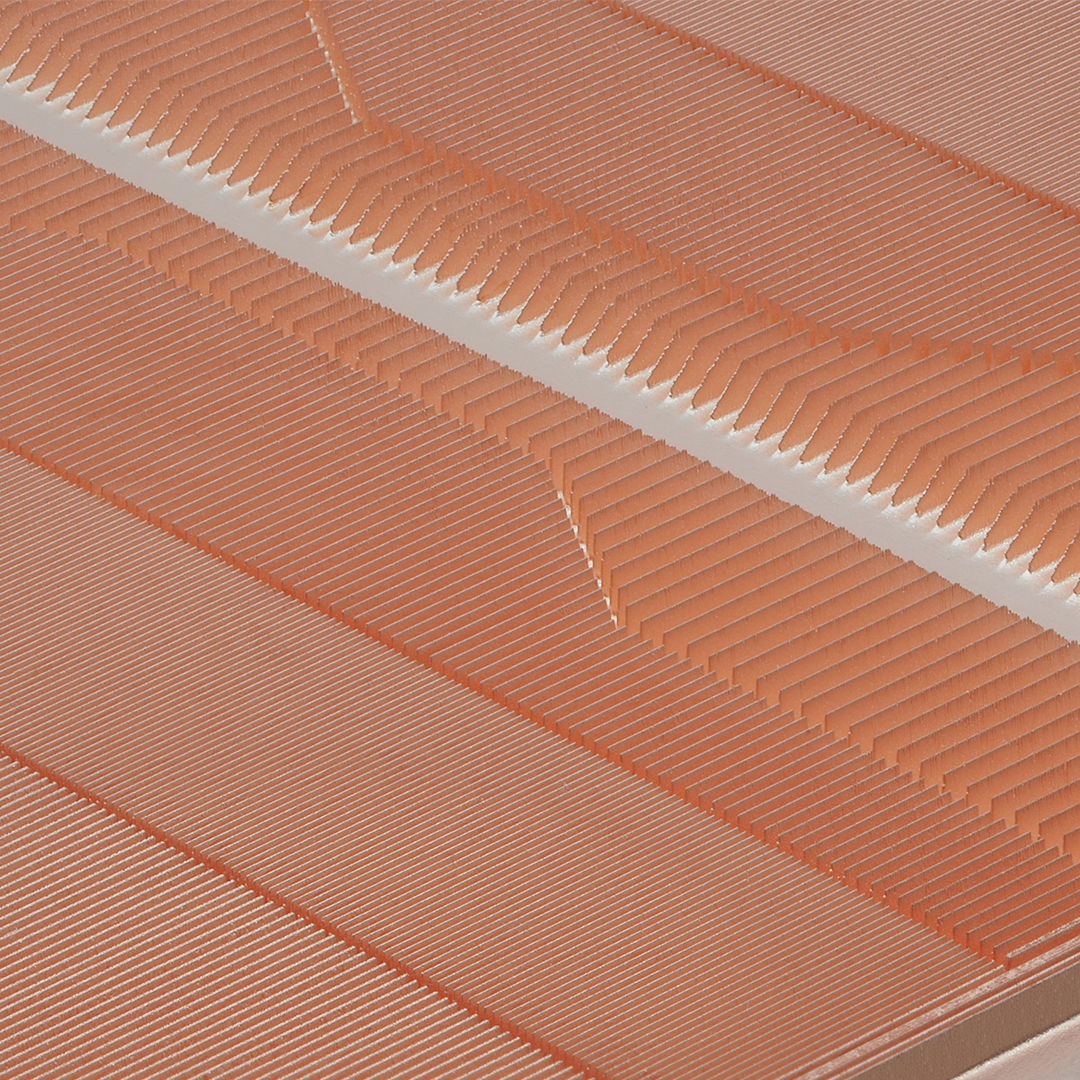

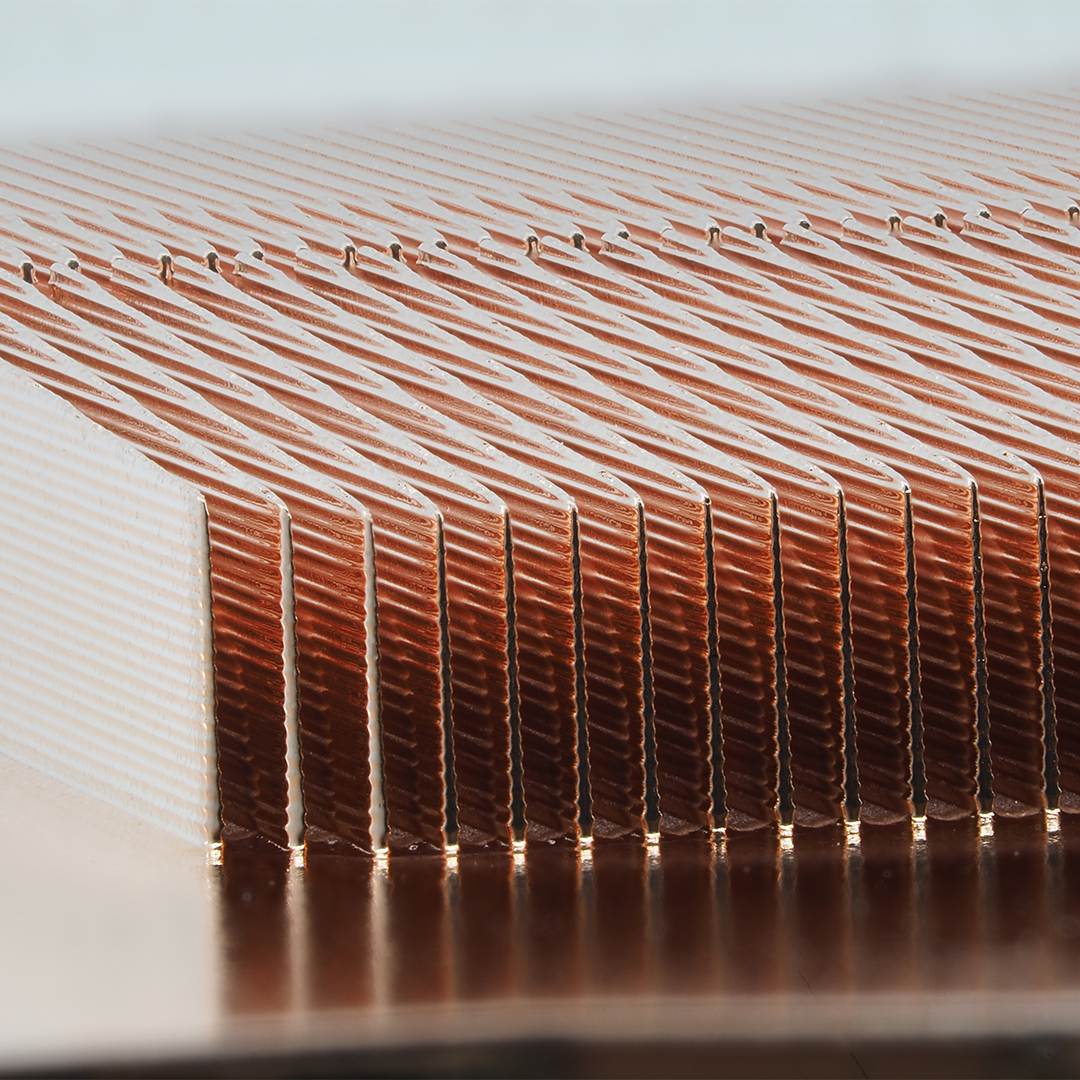

What is ECAM?

Electrochemical Additive Manufacturing (ECAM) is a breakthrough, room-temperature 3D printing technology that directly fabricates pure copper cold plates and advanced cooling hardware at micron-scale precision. Unlike traditional machining, skiving, or powder-based additive manufacturing, ECAM leverages a water-based process to build dense, high-conductivity copper features—enabling thermal designs previously impossible to manufacture. With ECAM, there’s no need for post-processing, bonding, or adhesives: designs go directly from digital file to finished part. This approach unlocks not only best-in-class thermal performance, but also mass customization and rapid iteration—delivering advanced liquid cooling solutions that are fully optimized for each device’s power map. Critically, ECAM is both scalable and cost competitive, supporting seamless transition from prototype to high-volume production, with the lowest total cost of ownership in the industry. As data centers confront rising power densities and relentless silicon innovation, ECAM sets the new standard for manufacturability, efficiency, and future-proof thermal management.

Why It Matters

- Best-in-Class Thermal Performance: Custom internal features mapped to real chip power profiles, eliminating hotspots and ensuring uniform die temperatures.

- Improve System Reliability: Apply thermal headroom to realize reliability through hardware lifetime.

- Frictionless Integration: Drop-in fit with existing assemblies, supply chains, and cooling loops—adopt advanced cooling with zero workflow disruption.

- Design Freedom & Mass Customization: Digital workflow enables rapid prototyping and application-specific optimization. Easily adapt to new silicon without tooling delays.

- Future-Proof Scalability: Seamlessly transition from prototype to mass production. Platform supports single-phase, two-phase, and immersion cooling as requirements evolve.

ECAM-Enabled Cooling Technologies

Single-Phase

Advanced copper microchannels deliver maximum efficiency and seamless drop-in integration—proven to lower total cost of ownership.

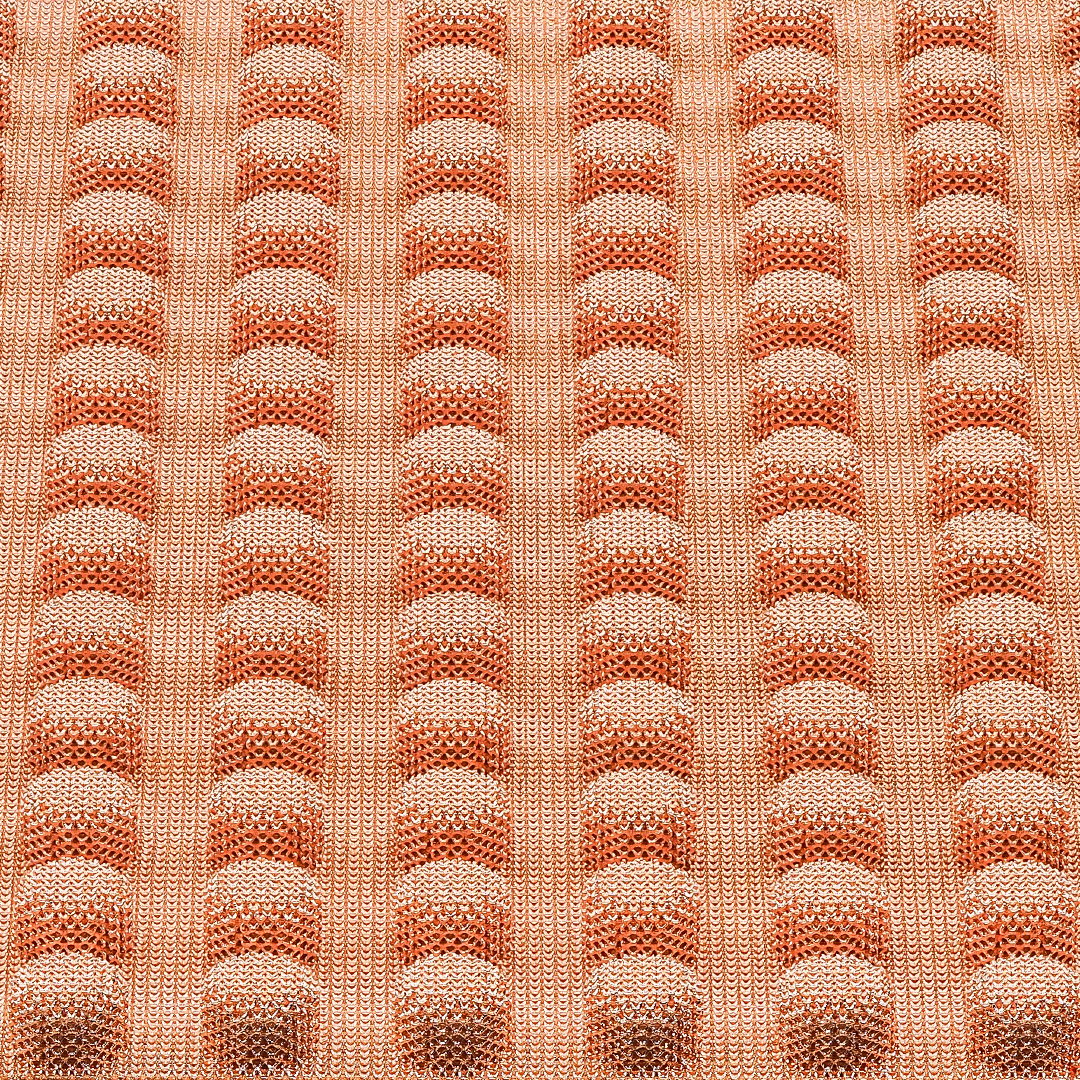

Two-Phase

ECAM enables precision boiling surfaces and engineered vapor pathways for unrivaled heat extraction in tomorrow’s AI and HPC workloads.

Custom Silicon

Work with Fabric8Labs to design cooling solutions optimized for your exact silicon, system, or facility—no compromise on performance.

Immersion Cooling

Unlock the future of cooling with direct-printed copper features engineered for high-efficiency immersion, supporting the densest racks and next-gen compute.