Electronics Manufacturing

Pushing the Boundaries of Resolution, Density, and Thermal Performance

ECAM for Electronics

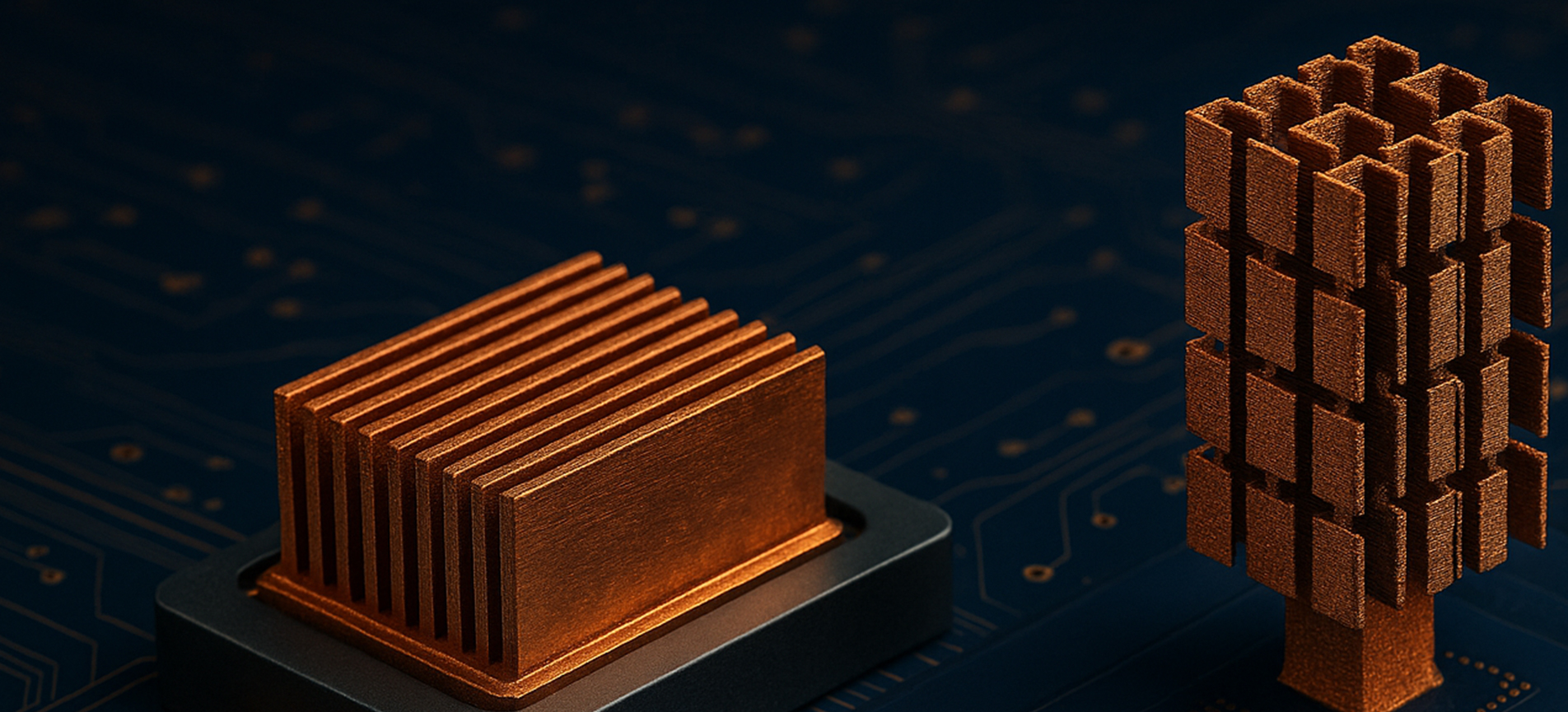

Fabric8Labs’ Electrochemical Additive Manufacturing (ECAM) is redefining what’s possible in electronics manufacturing. By printing pure metals—such as copper—at micron resolution directly onto PCBs, ceramics, and silicon, ECAM merges electrical, thermal, and mechanical performance into a single manufacturing step.

This capability unlocks:

-

Complex 3D Geometries that outperform traditional etched, plated, or machined parts.

-

Seamless Electrical & Thermal Integration by eliminating connectors, solder joints, and thermal interface materials.

-

Scalable Production from prototypes to millions of units without tooling delays or cost penalties.

Whether it’s compact power modules or chip-level cooling, ECAM enables designs that are smaller, faster, cooler, and more cost-effective—positioning electronics makers to lead in performance-critical markets.

Why Traditional Methods Limit Electronics Innovation

Resolution Ceiling

Conventional PCB etching and metal plating are fundamentally two-dimensional processes. They can’t deliver true 3D geometries or micron-scale features, forcing engineers to compromise on performance, integration, and form factor.

Assembly Overhead

Legacy manufacturing chains depend on soldering, bonding, and connectorization to join discrete components. These steps add cost, weight, and failure points — and every additional interface increases signal loss, especially at high frequencies.

Thermal Constraints

In most electronics, heat management is handled by bulky, bolt-on systems that sit apart from the electrical design. This separation introduces thermal resistance, increases system complexity, and limits the ability to address localized hotspots efficiently.

Material Restrictions

Many conventional processes cannot deposit high-purity copper directly onto temperature-sensitive substrates such as PCBs, ceramics, or silicon. As a result, designers are forced to use lower-conductivity materials or add intermediary bonding layers, both of which degrade electrical and thermal performance.

ECAM’s Electronics Advantage

Micron-Scale Precision

With a 33 µm voxel size, ECAM enables geometries that traditional methods simply cannot achieve — plus dense power interconnects and micro-cooling channels embedded directly into the device architecture.

Direct-to-Substrate Printing

ECAM prints directly onto PCBs, ceramics, silicon wafers, and metal foils at room temperature, avoiding the warping, delamination, or thermal damage that limits laser-based and high-heat processes.

High-Purity Metals

By depositing >99.95% pure copper, ECAM delivers industry-leading electrical and thermal conductivity — a critical edge for mmWave communications, high-current power electronics, and mission-critical systems.

No Post-Processing

Parts come off the printer in final form, with the surface finish, density, and tolerances required for direct use. No plating, sintering, or secondary machining is needed, eliminating waste and streamlining production.

Business Impact

- Lower Total Cost of Ownership: By consolidating multiple parts into a single ECAM build, eliminating connectors, and reducing assembly steps, ECAM cuts both material costs and long-term failure risk.

- Faster Time-to-Market: Digital manufacturing enables engineers to iterate designs in days instead of months — no tooling, no masks, and no dependency on slow, high-minimum-order suppliers.

- Design Freedom: Performance drives the design, not manufacturing limitations. ECAM’s voxel-level control allows engineers to integrate electrical, thermal, and mechanical functions in a single structure without compromise.

- Scalability: The same process used for a first prototype can produce millions of identical units with consistent quality. ECAM integrates seamlessly into high-volume electronics manufacturing, making scaling cost-efficient and low-risk.

Work with Fabric8Labs

The next generation of electronics demands more than yesterday’s manufacturing can deliver. With ECAM, you can integrate high-performance copper features directly onto your substrates, unlock designs that were once impossible, and bring products to market faster — all while lowering cost and risk.

Whether you need to optimize performance, shrink power electronics, or combine thermal and electrical functions in a single structure, our engineering team is ready to help you move from concept to production.

Take the next step today:

- Request a Design Review – Get expert feedback on how ECAM can optimize your design.

- See a Sample – Experience the precision, conductivity, and finish firsthand.

- Talk to an Engineer – Discuss your requirements and explore integration options.