Immersion Cooling

Designed for Phase Change

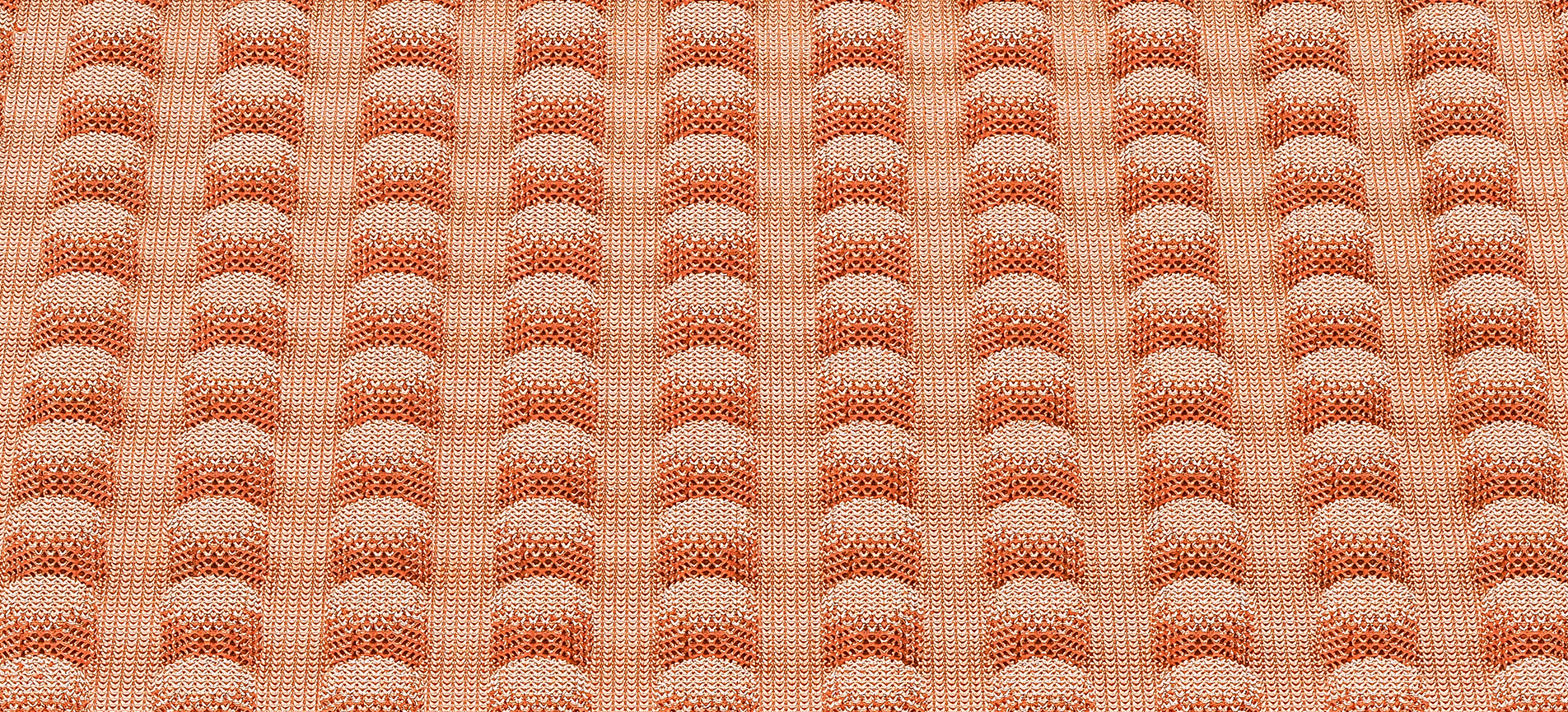

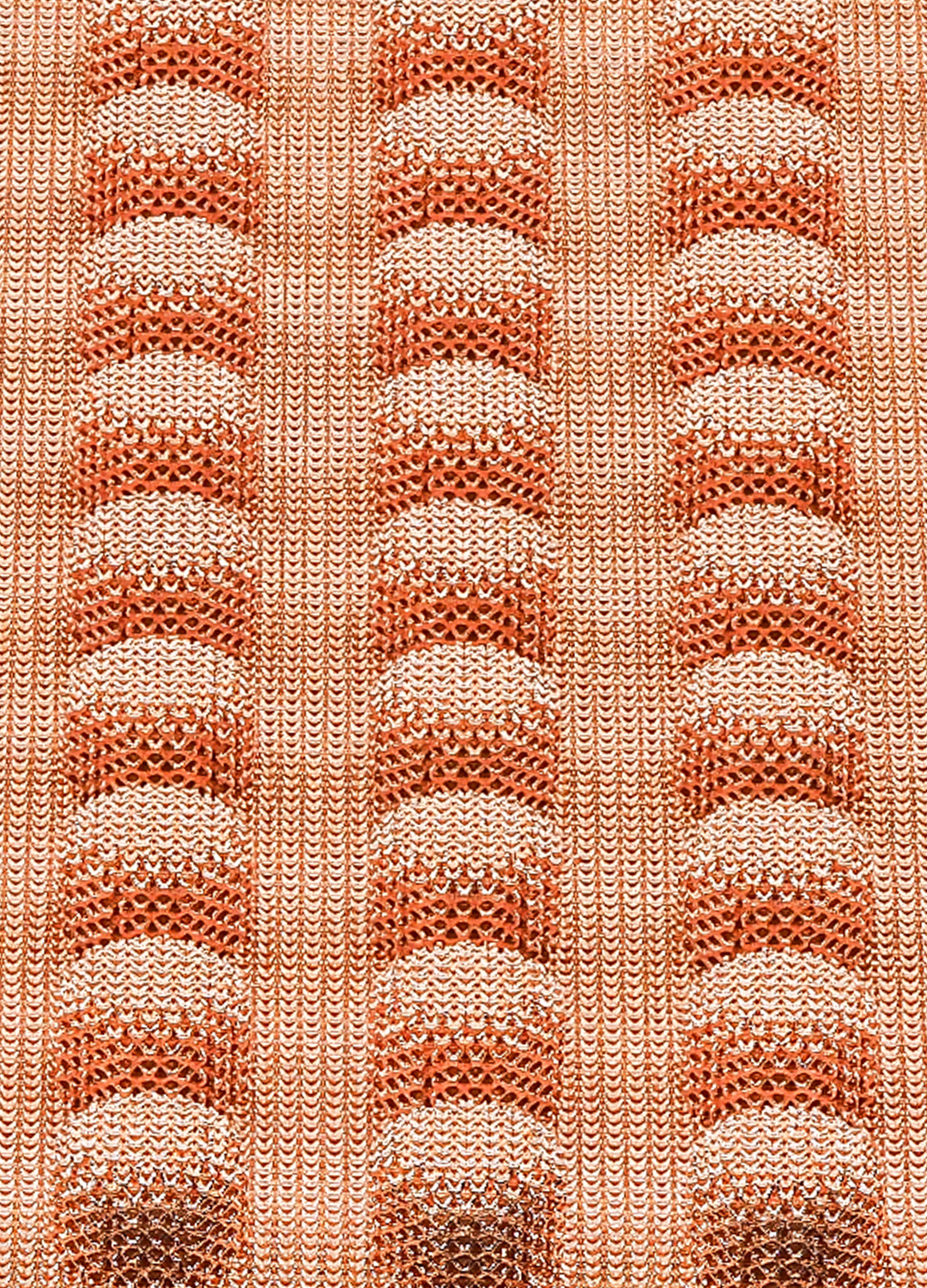

As power densities climb past the limits of traditional cold plates, immersion cooling offers a scalable path forward. Fabric8Labs builds immersion boiler plates that manage phase change with precision — delivering the ultra-fine surface features and material purity needed for efficient boiling and vapor flow control.

Why ECAM boiler plates make the difference:

-

Designed for Boiling Efficiency: Tailored surface textures and geometries for controlled nucleation

-

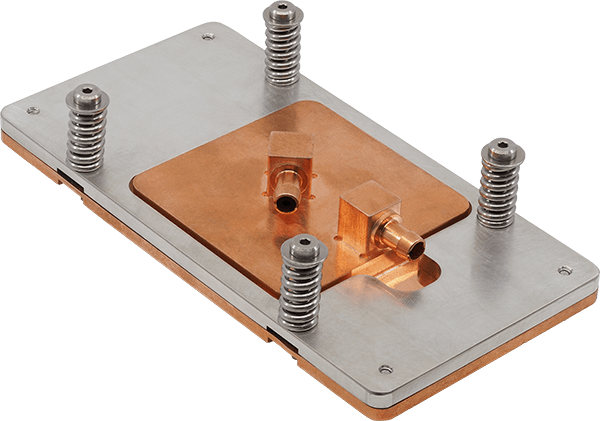

Copper Where It Counts: High-conductivity structures printed directly onto the heat source

-

Built to Scale: Mass production without sacrificing custom performance

Immersion Cooling with ECAM

Fabric8Labs uses Electrochemical Additive Manufacturing (ECAM) to create custom boiling surfaces with unmatched fidelity — without the manufacturing bottlenecks of machining, coating, or bonding. This room-temperature process enables copper to be grown directly onto silicon, ceramic, or metal substrates, reducing the number of thermal interfaces and minimizing resistance between the chip and coolant.

Our immersion boiler plates are designed to:

-

Maximize boiling surface area per mm² with fine-featured geometries

-

Enable consistent nucleation and vapor flow

-

Eliminate thermal interface layers for improved heat transfer

-

Support next-gen immersion and vapor chamber architectures

From early testbeds to full system rollouts, ECAM gives hardware teams the flexibility to tune their immersion strategy around real thermal data — not manufacturing constraints.

Prototype to Production

The ECAM platform supports the complete development cycle, from early design validation to high-volume manufacturing:

-

Rapid digital prototyping – Move from concept to functional hardware in days, enabling fast iteration and design refinement without tooling delays. This agility allows engineers to test multiple geometries in parallel and quickly converge on the optimal thermal solution.

-

Volume manufacturing – Produce high-precision inserts at scale with consistent geometry, material quality, and thermal performance. ECAM’s parallelized, room-temperature process ensures that scaling output does not compromise part accuracy or reliability, making it ideal for both niche and mass-market photonics applications.

-

Supply chain integration – Deliver fully finished, ship-to-line inserts ready for assembly by your preferred cold plate or optical module provider, ensuring seamless adoption into existing manufacturing workflows. Fabric8Labs can align production schedules, packaging, and quality assurance protocols with your current suppliers to accelerate deployment.

Proven Design Strategies

Fabric8Labs’ ECAM technology unlocks immersion boiling solutions engineered for the highest heat flux devices in the data center and AI compute landscape—from NVIDIA and AMD GPUs to next-generation custom accelerators. By directly integrating engineered copper boiling surfaces at the device interface, ECAM enables exceptional thermal transfer where it matters most.

- Power-Map Targeted Surfaces – ECAM creates micro- and nano-structured features precisely tuned to the heat distribution of high-TDP semiconductors, ensuring rapid vapor formation and consistent cooling across the die.

- Direct-to-Substrate Integration – Build advanced boiling surfaces directly onto silicon, ceramic, or metal baseplates without bonding or interface materials, eliminating thermal resistance and maximizing heat flux capacity.

- Reliability at Hyperscale – Monolithic, high-purity copper structures resist fouling, maintain stable nucleation characteristics, and sustain performance under the continuous duty cycles of AI and HPC environments.

ECAM Enables Best-In-Class Liquid Cooling

Unlock Mass-Customized, High-Performance Cooling with ECAM. Rapidly deploy optimized thermal solutions tailored for your most demanding high TDP applications. Get the technical data and performance curves – download our B200 case study.