Luxury Goods

Revolutionize Fine Jewelry Manufacturing with ECAM

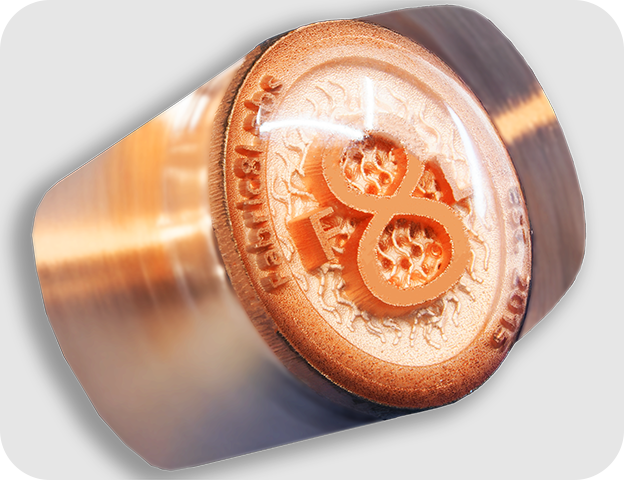

Fabric8Labs' Electrochemical Additive Manufacturing (ECAM) is transforming fine jewelry production by replacing traditional casting methods. ECAM eliminates wax models and reduces material waste, directly producing precision-built copper jewelry components ready for plating or use.

- Direct Metal Printing: Transition from CAD designs to finished metal parts, bypassing wax models for faster production.

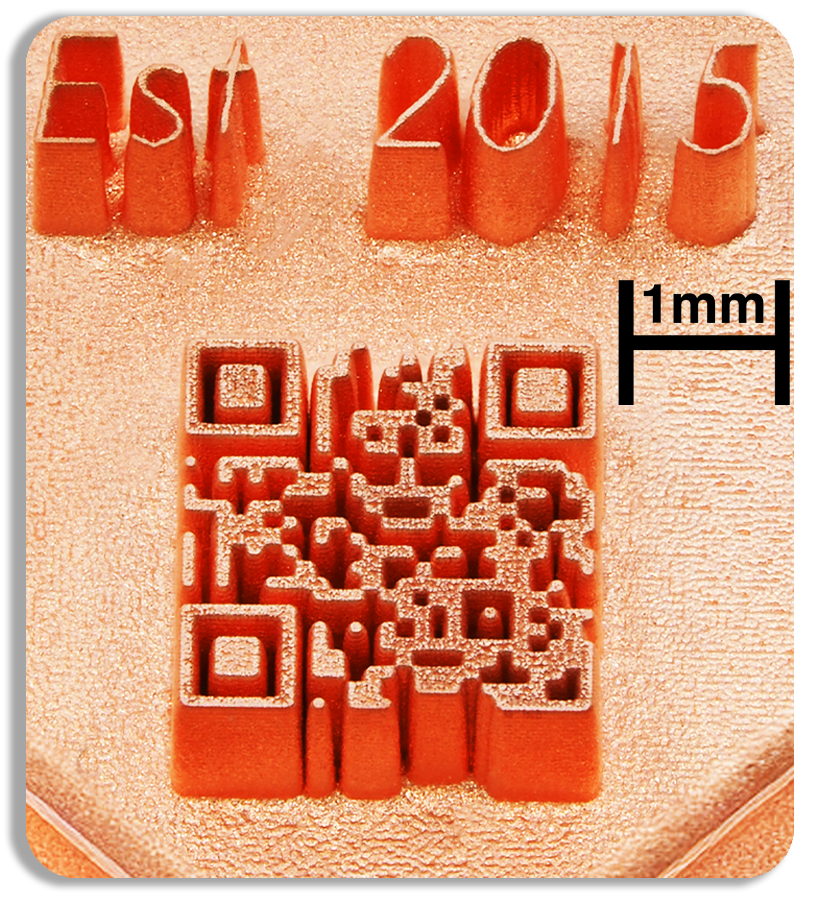

- Material Efficiency: Create intricate thin-walled and hollow geometries that significantly minimize the use of metals while maintaining design integrity.

- Ready-to-Finish Parts: Receive high-resolution, final-form components with minimal post-processing, streamlining the production workflow.

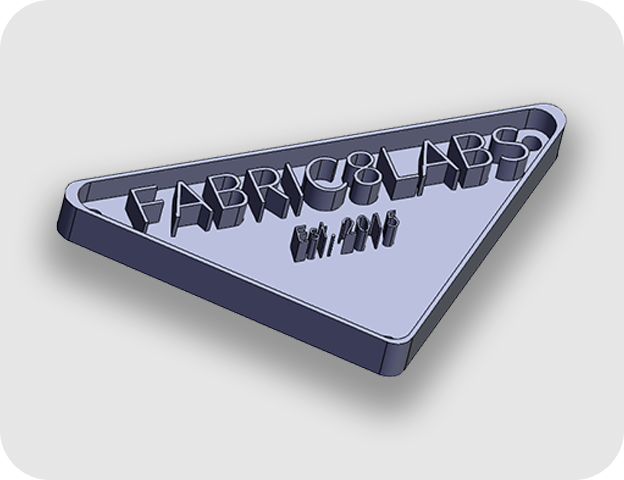

Direct from CAD to Precision Copper Jewelry

Fabric8Labs' ECAM delivers highly detailed, repeatable, high-purity copper jewelry components at scale. By eliminating wax, molds, and traditional supports, ECAM produces clean geometries with minimal finishing, ready for electroplating or direct integration with your other Pieces.

Using a room-temperature, support-free electrochemical process, ECAM builds final metal parts directly from your CAD files. This direct manufacturing approach avoids casting, shrinkage, and wax waste, thus ensuring a precise match to your design. Unlike other metal AM technologies like binder jetting or PBF, ECAM parts do not require post-print sintering and thus avoid thermal distortion.

Process:

- CAD File Upload: Submit standard files, or optimize with our guidance.

- Pure Metal Printing: Currently printing in copper, with precious metals in development.

- Ready-to-Finish Parts: Receive clean, high-resolution components for plating, finishing, or assembly.

Join us in shaping the future of jewelry. Copper is available now, and we're collaborating on ECAM workflows for gold, silver, and rhodium. Contact us for samples, custom prints, or partnerships. Let’s build the future of jewelry together.

Copper is available today. We’re actively partnering with jewelers, manufacturers, and designers to co-develop ECAM workflows for gold, silver, and rhodium.

Contact us to collaborate, request a sample, or explore a custom print for your next launch.

Contact Us