Photonics Cooling

Maximizing performance and reliability in high-power lasers and optical interconnects through advanced liquid cooling.

Next-Generation Optical Performance

High-power photonic systems, including industrial laser arrays and hyperscale optical interconnects, demand precise thermal control to maintain peak performance. Even small temperature fluctuations can shift wavelengths, reduce optical power, and accelerate component degradation.

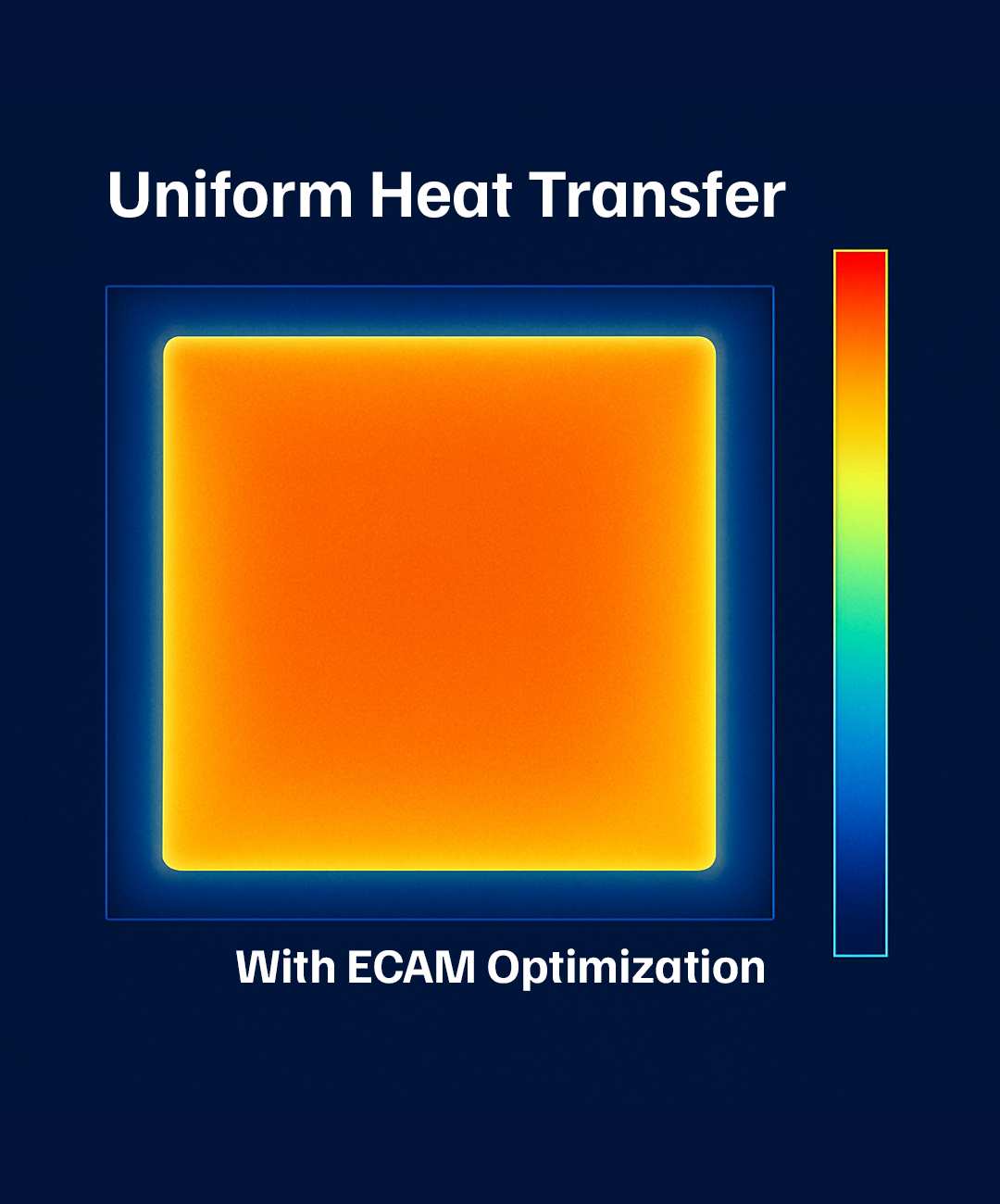

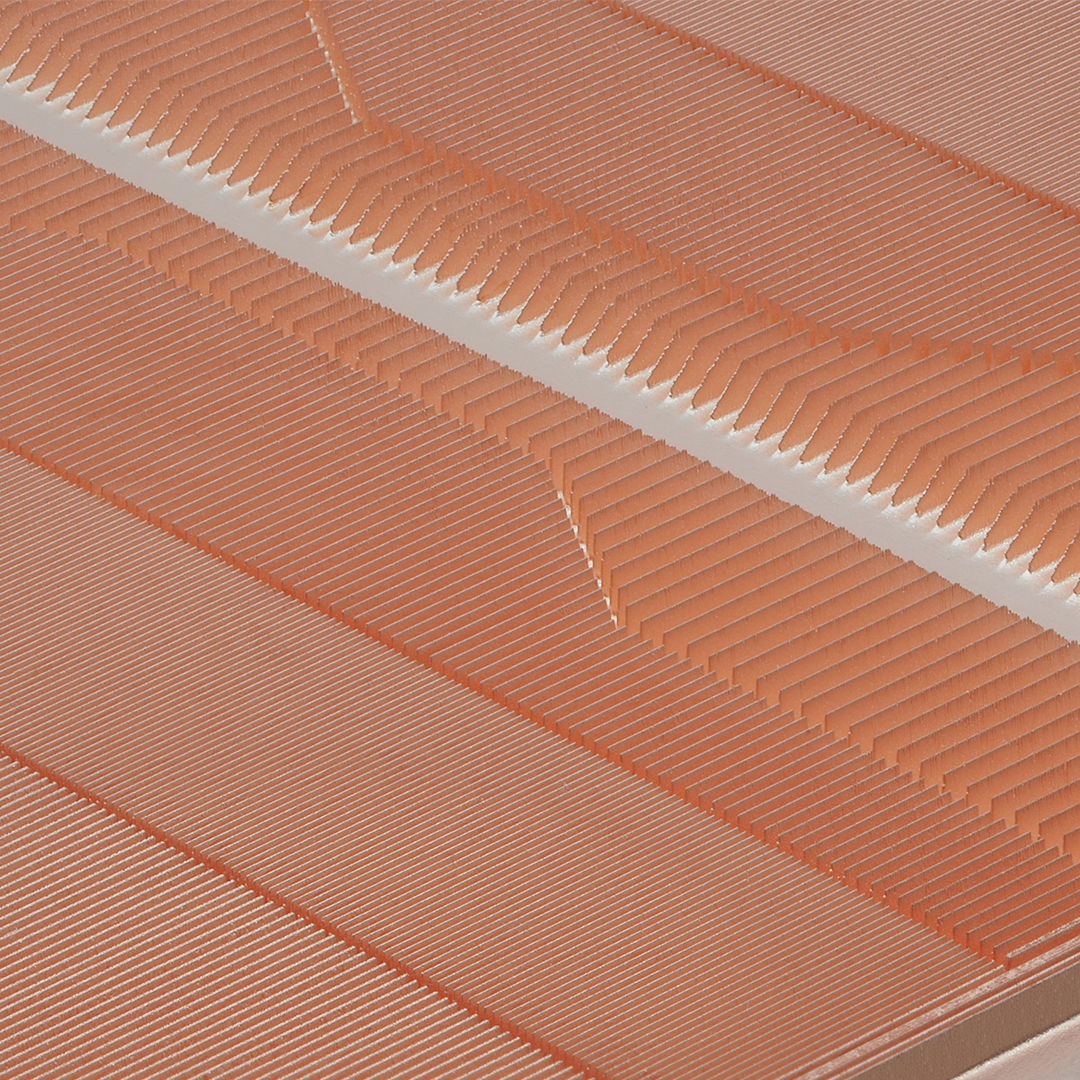

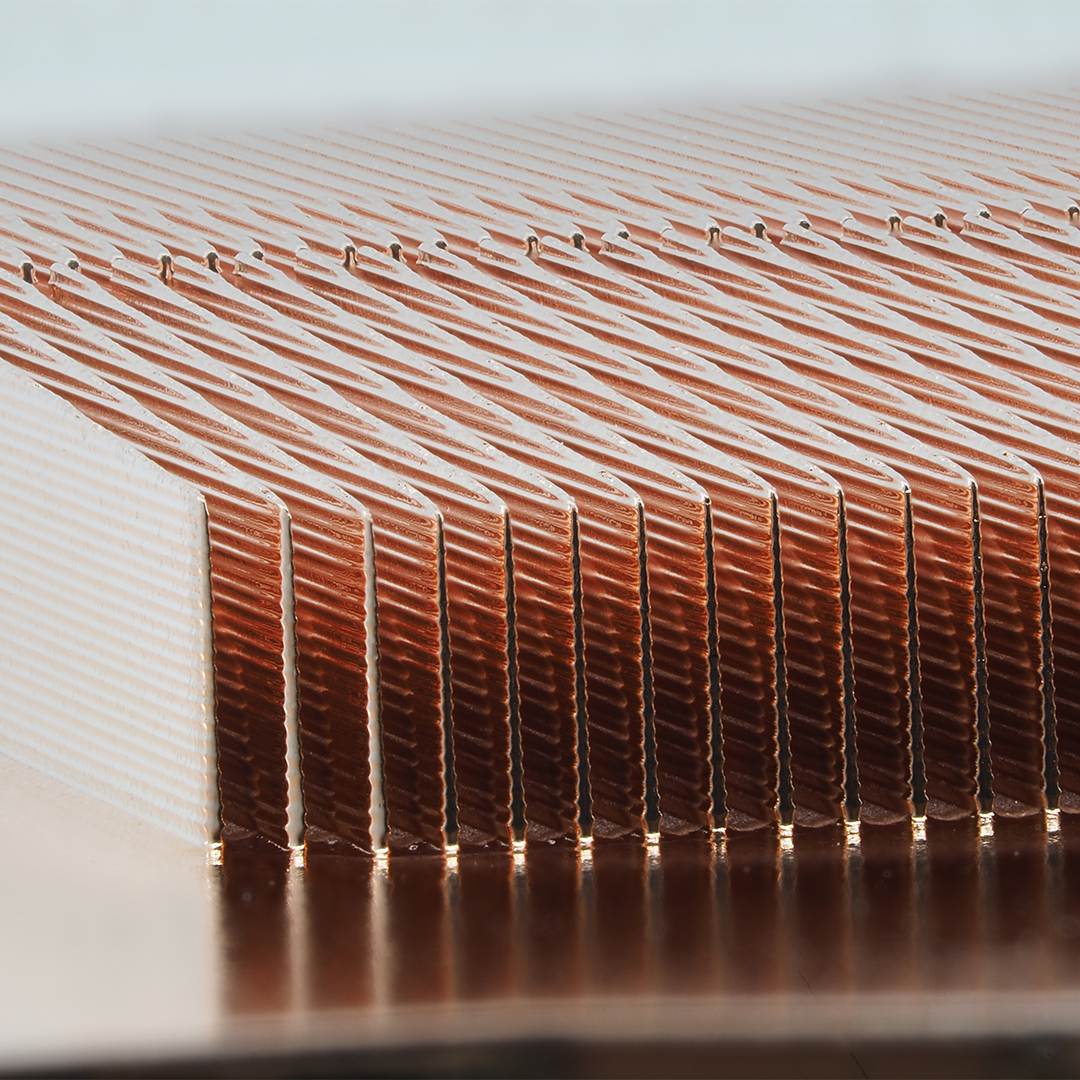

Fabric8Labs’ Electrochemical Additive Manufacturing (ECAM) enables production of pure copper liquid cooling solutions with micron-scale precision, tailored to the exact thermal profile of each device. By integrating high-conductivity copper structures directly onto substrates such as silicon, ceramics, or metallized optical packages, ECAM eliminates thermal interface materials and optimizes heat transfer at the source.

The result is stable wavelength performance, higher sustained optical output, and extended component life—delivered through a scalable, drop-in manufacturing process compatible with high-volume photonics production.

High-Power Laser Diodes

Laser diodes used in industrial processing, defense, and advanced communications can generate heat loads exceeding hundreds of watts per emitter bar, creating thermal densities that overwhelm conventional microchannel plates. ECAM provides a direct path to higher performance through:

-

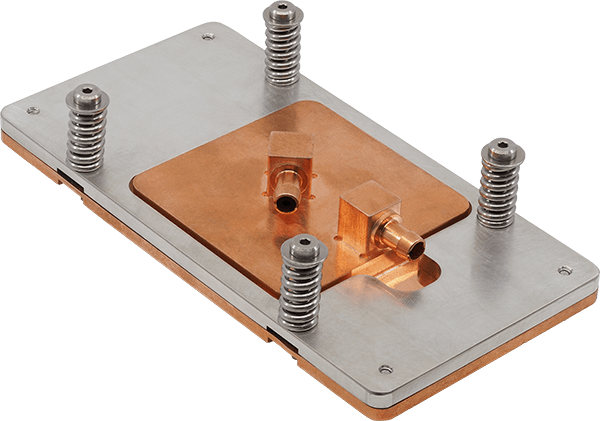

Power-map-optimized cold plate inserts with internal fins, lattices, and flow channels engineered to target localized hot spots in diode arrays.

-

Pure copper structures (>99% density) for maximum thermal conductivity and minimal optical alignment drift.

-

Direct integration to precision baseplates with sub-micron flatness, preserving beam quality and mechanical stability.

Impact: Consistent optical output at higher drive currents, longer device lifespan, and lower active cooling energy requirements.

QSFP and OSFP Fiber Connectors

Pluggable transceivers for 800G and next-generation optical devices compress high-power DSPs, drivers, and laser subassemblies into extremely tight footprints. ECAM enables high-efficiency thermal solutions within these constraints through:

-

Micro-cold plates with ultra-low profile to fit seamlessly inside standard connector envelopes.

-

Targeted cooling zones for critical optoelectronic components, ensuring stable performance under sustained full traffic loads.

-

Low-pressure-drop internal geometries that reduce impact on overall system pump power.

Impact: Greater link stability, higher allowable ambient operating temperatures, and extended mean time between failures for mission-critical optical networks.

ECAM Advantage in Photonics Cooling

Fabric8Labs’ Electrochemical Additive Manufacturing (ECAM) delivers a step-change in thermal management for photonics hardware by combining precision, integration flexibility, and production scalability.

-

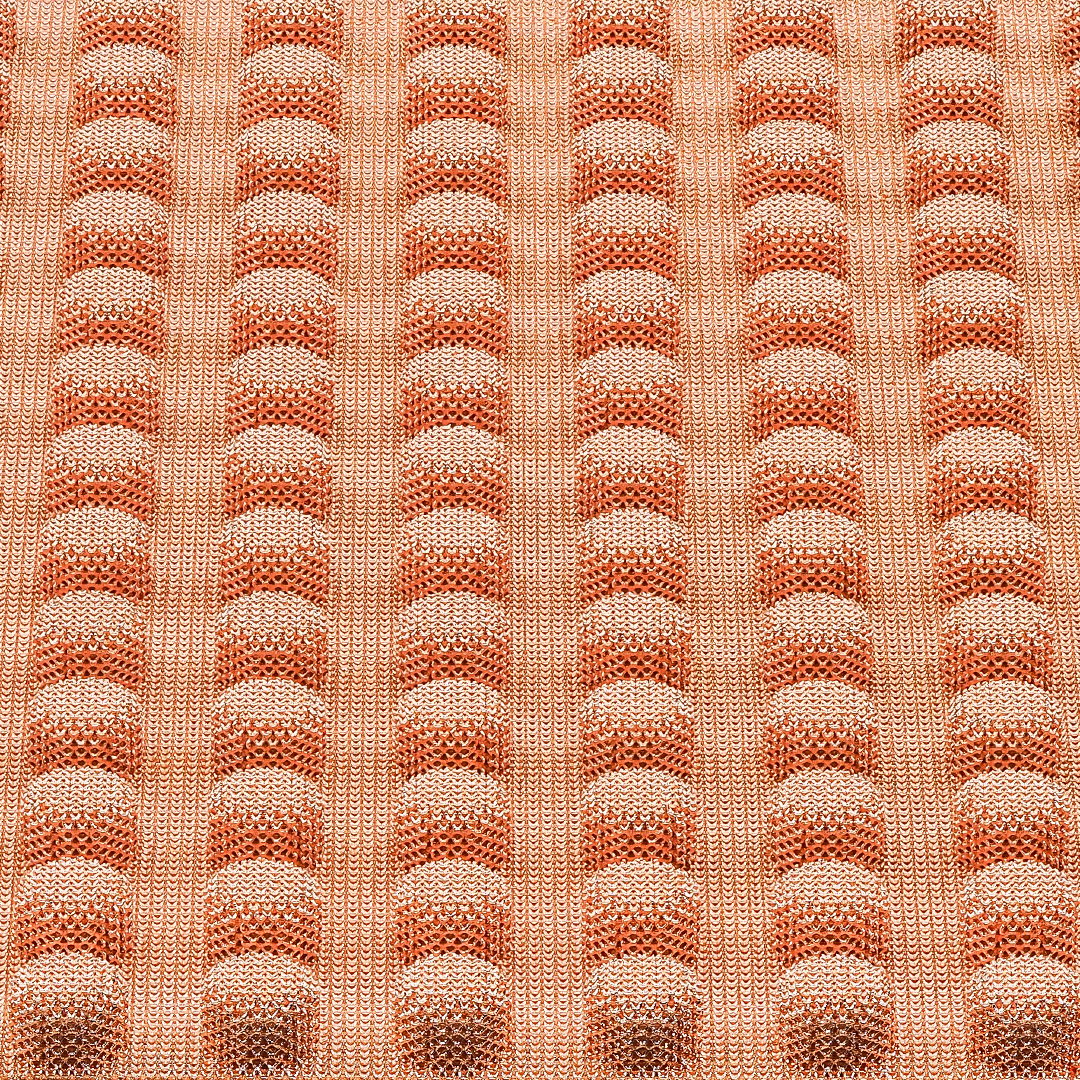

Micron-scale internal features – Create channels, posts, and porous structures at 33 µm voxel resolution to precisely manage coolant flow and maximize heat transfer.

-

Direct-to-substrate printing – Deposit pure copper directly onto ceramics, silicon, or metallized baseplates without bonding layers or thermal interface materials, reducing thermal resistance and improving reliability.

-

Thermal performance headroom – Achieve up to 900% more surface area compared to flat channels, enabling exceptional heat flux removal for high-power optical devices.

-

Drop-in compatibility – ECAM inserts fit seamlessly into existing liquid cooling hardware, accelerating deployment without redesigning system architectures.

-

Lowest total cost of ownership – Remove the need for bonding steps, costly metal powders, and tooling, allowing faster design iterations and efficient scaling to production.

From Prototype to Production

The ECAM platform supports the complete photonics development cycle, from early design validation to high-volume manufacturing:

-

Rapid digital prototyping – Move from concept to functional hardware in days, enabling fast iteration and design refinement without tooling delays. This agility allows engineers to test multiple geometries in parallel and quickly converge on the optimal thermal solution.

-

Volume manufacturing – Produce high-precision inserts at scale with consistent geometry, material quality, and thermal performance. ECAM’s parallelized, room-temperature process ensures that scaling output does not compromise part accuracy or reliability, making it ideal for both niche and mass-market photonics applications.

-

Supply chain integration – Deliver fully finished, ship-to-line inserts ready for assembly by your preferred cold plate or optical module provider, ensuring seamless adoption into existing manufacturing workflows. Fabric8Labs can align production schedules, packaging, and quality assurance protocols with your current suppliers to accelerate deployment.

Proven Design Strategies for Photonics

ECAM enables photonics cooling solutions that are both performance-optimized and production-ready. Designs are tailored to match each application’s unique thermal and mechanical requirements:

-

Power-map optimization – Custom microchannel layouts match the exact thermal profile of laser diodes, transceivers, or optical subassemblies, ensuring targeted cooling where it is needed most.

-

Hybrid baseplate integration – Combine conventionally machined optical mounts with ECAM-printed microstructures in a single assembly, uniting precision optical alignment with advanced heat removal.

-

Reliability at scale – Monolithic pure copper features minimize leak paths, resist fouling, and maintain consistent performance over long operational lifetimes.

ECAM-Enabled Cooling Technologies

Single-Phase

Advanced copper microchannels deliver maximum efficiency and seamless drop-in integration—proven to lower total cost of ownership.

Two-Phase

ECAM enables precision boiling surfaces and engineered vapor pathways for unrivaled heat extraction in tomorrow’s AI and HPC workloads.

Custom Silicon

Work with Fabric8Labs to design cooling solutions optimized for your exact silicon, system, or facility—no compromise on performance.

Immersion Cooling

Unlock the future of cooling with direct-printed copper features engineered for high-efficiency immersion, supporting the densest racks and next-gen compute.

ECAM Enables Best-In-Class Liquid Cooling

Unlock Mass-Customized, High-Performance Cooling with ECAM. Rapidly deploy optimized thermal solutions tailored for your most demanding high TDP applications. Get the technical data and performance curves – download our B200 case study.